Headphone Mesh Defect Detection with 3D Laser Profilers

Industry pain points and demands

In the consumer electronics industry, particularly in headphone manufacturing, the miniaturization of components has led to increased complexity in production. Delicate parts like headphone meshes play a critical role in determining both the lifespan and sound quality of headphones. Defects such as deformation and compression damage can significantly impact performance and user satisfaction. Therefore, it is essential to implement effective inspection processes during production to identify these defects early.

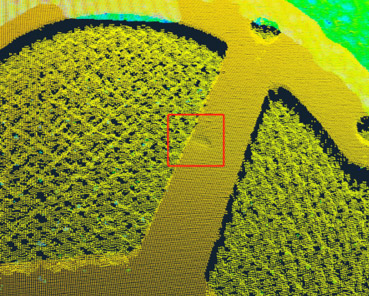

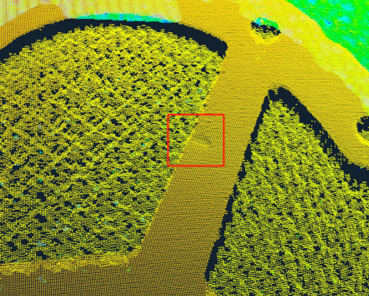

Physical Picture or Imaging Effect Picture

SinceVision Solutions: SR8020 3D Laser Profiler

01High Precision Measurement: The SR8020 3D Laser Profiler achieves a remarkable sampling resolution of 0.005mm × 0.005mm and a sampling frequency of 13kHz. This level of precision ensures that even the smallest defects in headphone meshes are detected, maintaining high-quality standards in production.

02Comprehensive Imaging Capabilities: The SR8020 provides excellent imaging results for various defect types, including bracket compression damage, deformation, mesh compression damage, and steel mesh exceeding brackets. This versatility allows manufacturers to address multiple quality control needs with a single solution.

03Stable Performance in Dynamic Environments: Designed for stability, the SR8020 can be integrated with brightness mapping for enhanced calculations. This feature ensures consistent performance even in challenging production environments, allowing for reliable defect detection regardless of external factors.

Camera Selection

| Model number | SR8020 | |||

| Reference distance (CD) | 23mm | |||

| Measuring range | Z-axis height (FS) | 5.2mm | ||

| X-axis width | Near side | 13mm | ||

| Reference distance | 14.5mm | |||

| Remote side | 16mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.15μm | ||

| X-axis (width) | 1.5μm | |||

| linearity | Z-axis (height) | ±0.02% of F.S. | ||

| Contour data interval | X-axis (width) | 5μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 41.5 | |||

| Scanning speed (Hz) | 3200 ~ 67000 | |||

| Dimension (mm) | 125.5×82×55 | |||

| Weight (g) | 650 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential encoder is supported | |||

| Input/output | One 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs (10-500Hz), compliant with IEC 68-2-6 Fc standard | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||