Sealing Detection of Kinder Joy Eggs with SinceVision 3D Laser Profiler

Industry pain points and demands

Ensuring proper sealing of Kinder Joy eggs is crucial to maintain product freshness, safety, and consumer trust. Irregular or faulty seals can result in contamination, spoilage, and compromised product integrity. Conventional inspection methods often lack the precision and adaptability needed for high-speed production lines with uniquely shaped products like Kinder Joy eggs.

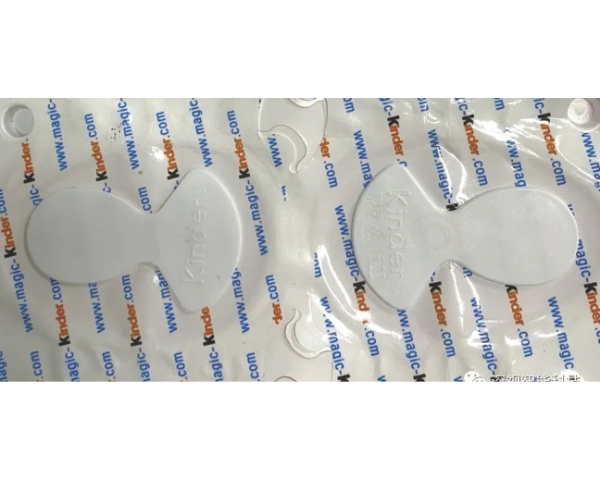

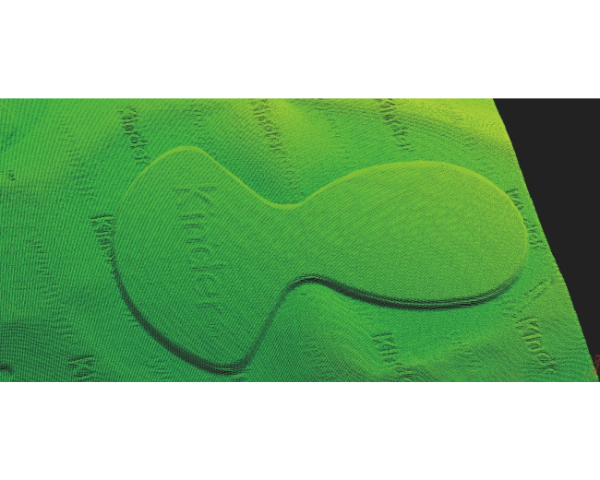

Physical Picture or Imaging Effect Picture

SinceVision Solution: SR7900/SR7300 3D Laser Profiler

01Precise Seal Inspection: Accurately detects sealing defects such as gaps, misalignments, or weak points to prevent contamination and spoilage.

02Adaptable Design: Designed for versatile use, it seamlessly handles Kinder Joy's unique shapes and varying packaging materials.

03Real-Time Quality Control: Operates efficiently on high-speed production lines, offering instant feedback to reduce waste and ensure product safety.

Camera Selection

| Model number | SR7900 | |||

| Reference distance (CD) | 900mm | |||

| Measuring range | Z-axis height (FS) | 500mm | ||

| X-axis width | Near side | 359mm | ||

| Reference distance | 489mm | |||

| Remote side | 576mm | |||

| Light source | Light source wavelength | 450nm blue light | ||

| Laser class | 3R | |||

| Laser output power | 50mW | |||

| Repetition accuracy | Z-axis (height) | 12μm | ||

| X-axis (width) | 40μm | |||

| linearity | Z-axis (height) | ±0.05% F.S. | ||

| Contour data interval | X-axis (width) | 180μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 13 | |||

| Scanning speed (Hz) | 2500 ~ 8000 | |||

| Dimension (mm) | 275.5×98.5×59 | |||

| Weight (g) | 1300 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential coders are supported | |||

| Input/output | One 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs(10-500Hz)符合 IEC 68-2-6 Fc标准标准 | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||

| Model number | SR7300 | |||

| Reference distance (CD) | 300mm | |||

| Measuring range | Z-axis height (FS) | 288mm | ||

| X-axis width | Near side | 175mm | ||

| Reference distance | 290mm | |||

| Distal end | 320mm | |||

| Light source | Light source wavelength | 405nm blue light | ||

| Laser class | 3R | |||

| Laser output power | 50mW | |||

| Repetition accuracy | Z-axis (height) | 8μm | ||

| X-axis (width) | 45μm | |||

| linearity | Z-axis (height) | ±0.05% F.S. | ||

| Contour data interval | X-axis (width) | 100μm | ||

| X-axis contour points | 3200 | |||

| Reflection Angle (°) | 22 | |||

| Scanning speed (Hz) | 1000 ~ 4000 | |||

| Dimension (mm) | 192.5×105.2×59 | |||

| Weight (g) | 1145 | |||

| Temperature characteristic | 0.02% F.S./℃ | |||

| Encoder input | Single-ended, differential coders are supported | |||

| Input/output | One 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | 10Gs(10-500Hz)符合 IEC 68-2-27 Ea标准标准 | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||