Welding Quality Inspection of Top Cover with SinceVision 3D Laser Profiler

Industry pain points and demands

The welding of the top cover is a crucial step in sealing square power lithium batteries, directly impacting the safety and stability of the entire product. Identifying welding quality issues quickly and accurately is essential to minimizing safety risks. With the SinceVision 3D Laser Profiler, advanced 3D machine vision technology enhances inspection processes, ensuring precise evaluation of welding quality for top covers in lithium battery production.

SinceVision Solution: SR8060C 3D Laser Profiler

01High Precision: Achieves XYZ sampling resolution of 0.012mm×0.027mm×0.0012mm, ensuring accurate detection of welding quality for lithium battery top covers.

02Fast Speed: Delivers an impressive actual sampling speed of 300mm/s, improving production efficiency in lithium battery manufacturing.

03Cost-Effective: Offers a significant cost advantage under the same configuration, making it a reliable choice for precision and affordability.

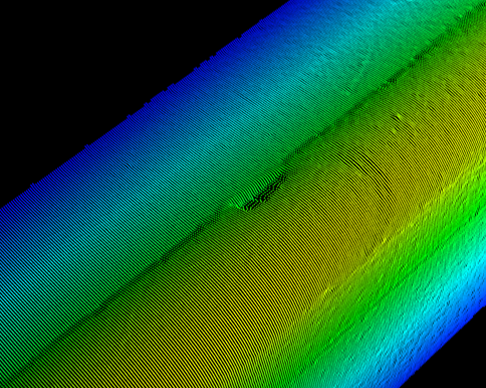

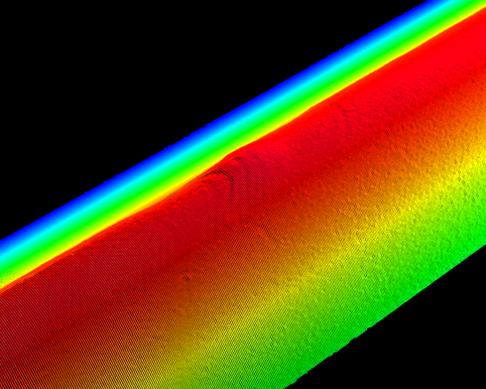

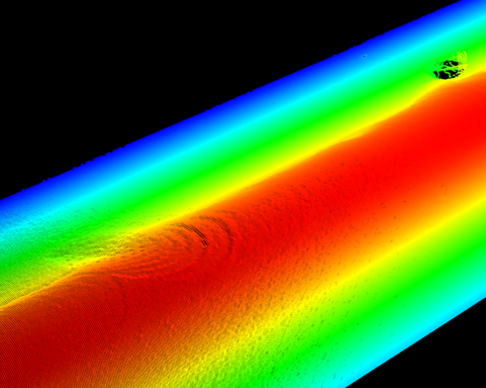

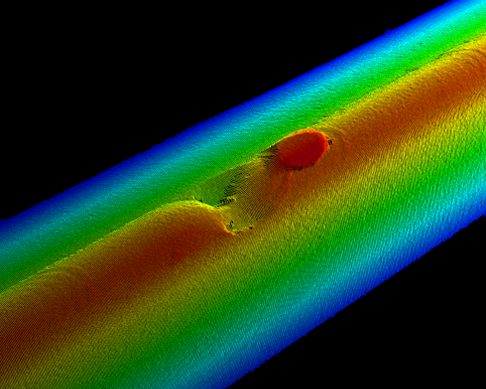

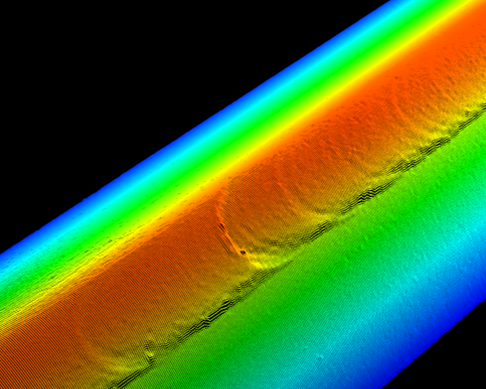

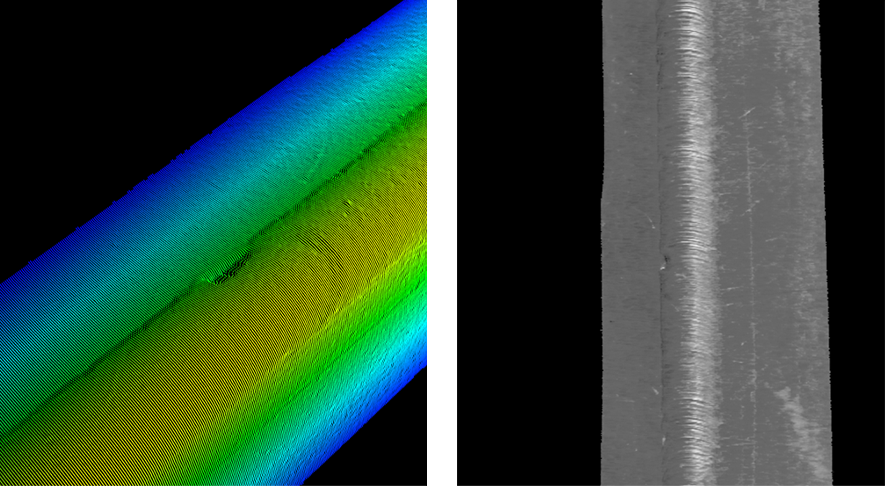

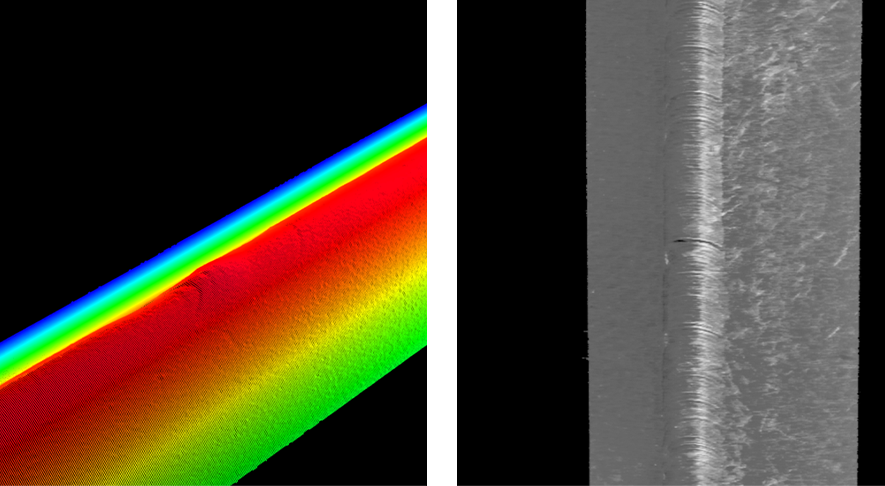

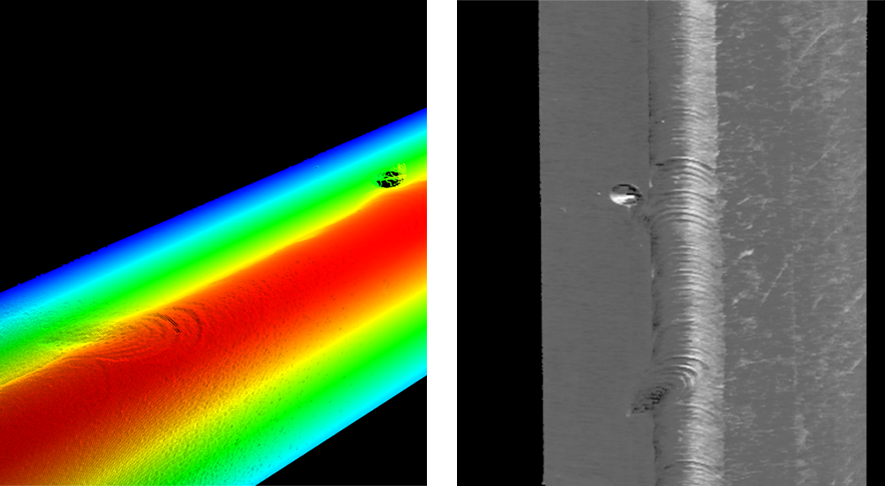

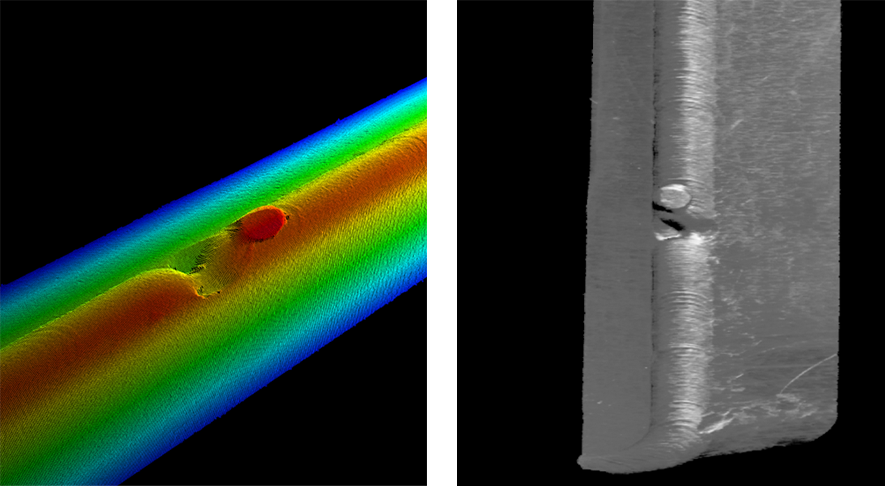

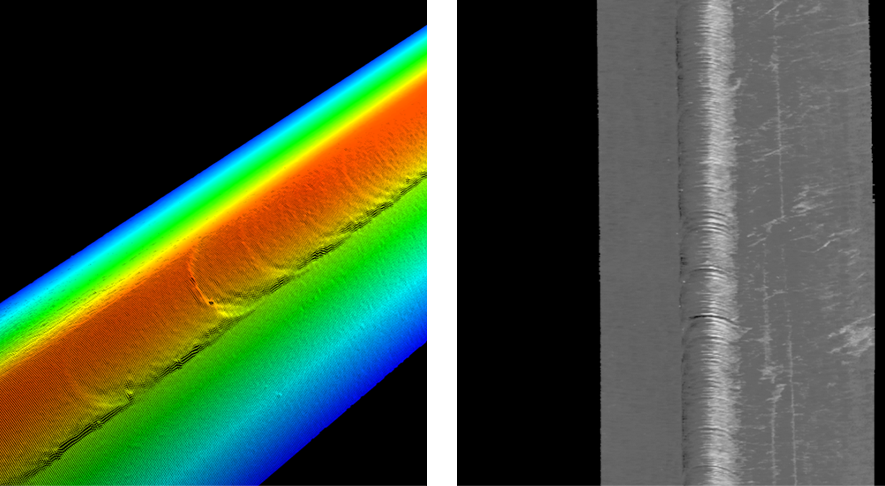

Effect display

Camera Selection

| Model number | SR8060C | |||

| Reference distance (CD) | 60mm | |||

| Measuring range | Z-axis height (FS) | 18mm | ||

| X-axis width | Proximal end | 30mm | ||

| Reference distance | 20mm | |||

| Distal end | The 31.5 mm | |||

| Light source | Light source wavelength | 405nm | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.2 um | ||

| X-axis (width) | 0.2 um | |||

| linearity | Z-axis (height) | ±0.02% FS | ||

| Contour data interval | X-axis (width) | 10um | ||

| X-axis contour points | 3200 | |||

| Scanning speed (Hz) | 2500 ~ 8000 | |||

| I/O interface | 8 programmable input interfaces, 8 programmable output interfaces | |||

| Encoder interface | One single end, one difference encoder | |||

| Input/output | One RS232 interface and one 100Base-TX/1000Base-T Ethernet interface | |||

| Operating temperature | 0 to 45°C | |||

| Storage temperature | -20 to 70°C | |||

| Working humidity | 35% to 85% no condensation | |||

| ESD protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC61000-4-2 standard | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, compliant with IEC61000-4-4 standard | |||

| Impact | 50Gs/3ms per axis, in accordance with IEC 68-2-27 Ea | |||

| Vibration | 10Gs(10-500Hz)符合 IEC 68-2-6 Fc标准 | |||

| IP level | IP67 | |||

| Size (mm) | 160 x 98 x 48 | |||

| Data cable (wiring) model | SCB-HCAM-HB1-3m、SCB-HCAM-HB1-10m | |||

| Weight | 750g | |||