Laser displacement sensors play a crucial role in modern industrial automation. Among the advanced solutions, SinceVision's SG Series stands out, setting new standards in laser displacement measurement and sensor technology. This article explores its groundbreaking capabilities, explains the technology behind it, and highlights its benefits for various industries.

What is a Laser Displacement Sensor?

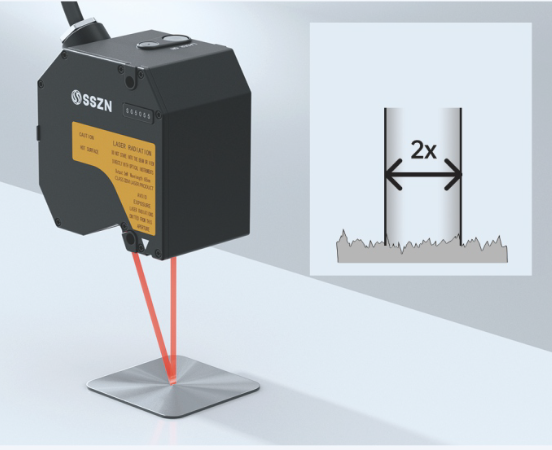

Image: SG3030 Laser Displacement Sensor

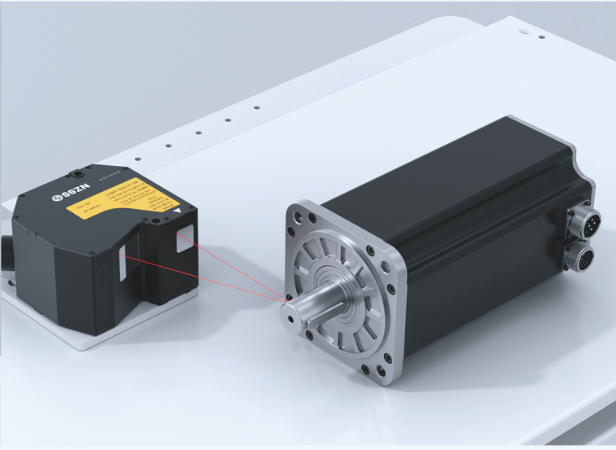

At its core, a laser displacement sensor measures distances by projecting a laser onto a target and capturing its reflection. These devices offer non-contact displacement measurement, ensuring high precision and stability. The SG Series by SinceVision uses cutting-edge triangular reflection technology to provide unmatched accuracy in detecting positions and distances.

How Does It Work?

The SG Series leverages the triangular reflection principle:

1. A laser spot projects onto the target.

2. The reflected light strikes a photosensitive sensor.

3. Depending on the target’s distance, the spot’s position shifts on the sensor.

4. This shift is converted into highly accurate displacement measurements.

This straightforward process ensures precise, repeatable measurements in diverse industrial environments.

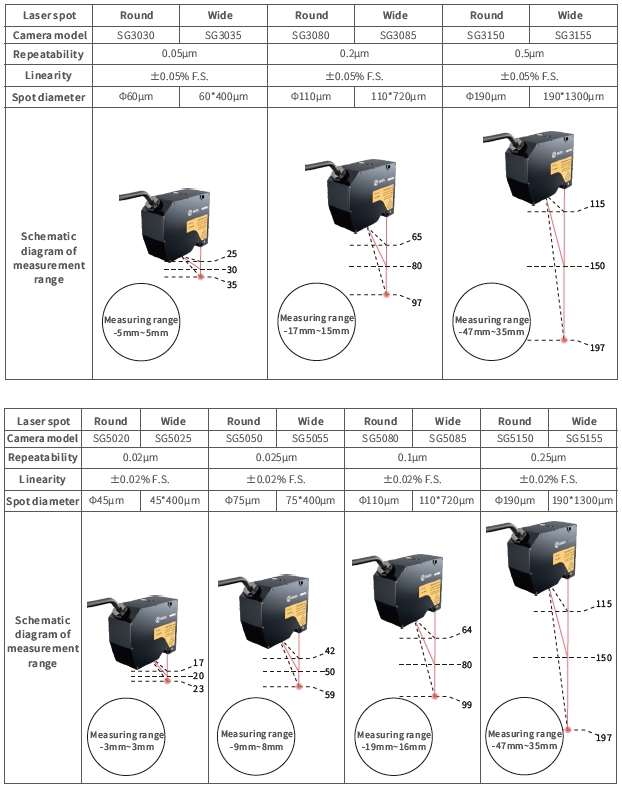

Key Features of the SG Series

The SG Series Laser Displacement Sensors are engineered to tackle the challenges of high-speed, high-precision tasks. Here are the standout features that make this product a preferred choice for industrial applications:

a. Round Laser Spot

The ultra-small, round spot is designed to detect fine component contours, essential for intricate tasks like semiconductor or electronic component manufacturing.

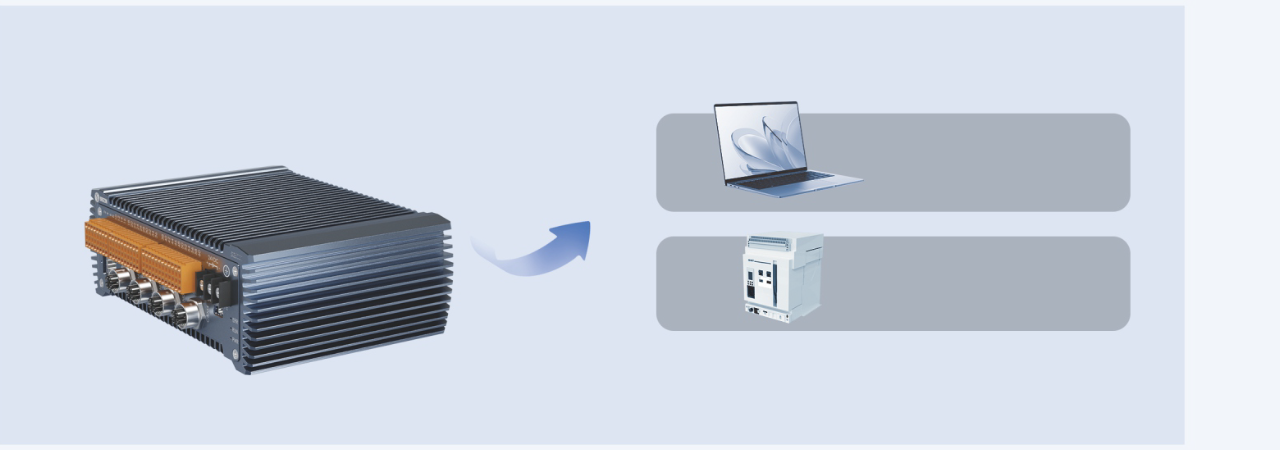

b. Multiple Communication Methods

The SG Series supports network port TCP/IP, ModbusTCP, and RS232 communications. Whether handling complex automation systems or simple setups, its compatibility ensures ease of integration.

The SG Series supports network port TCP/IP, ModbusTCP, and RS232 communications. Whether handling complex automation systems or simple setups, its compatibility ensures ease of integration.

c. One-to-Four Controller

A single controller can handle up to four sensor heads, simultaneously outputting eight different measurements. This enhances efficiency and cost-effectiveness.

A single controller can handle up to four sensor heads, simultaneously outputting eight different measurements. This enhances efficiency and cost-effectiveness.

d. Wide Laser Spot

For materials with varying surface textures like rough metal or plastic, the sensor eliminates the influence of surface roughness, ensuring stable measurements.

e. Ultra-High Sampling Frequency

The SG Series boasts an impressive sampling frequency of up to 590kHz, capturing movements of fast-moving objects without compromising accuracy.

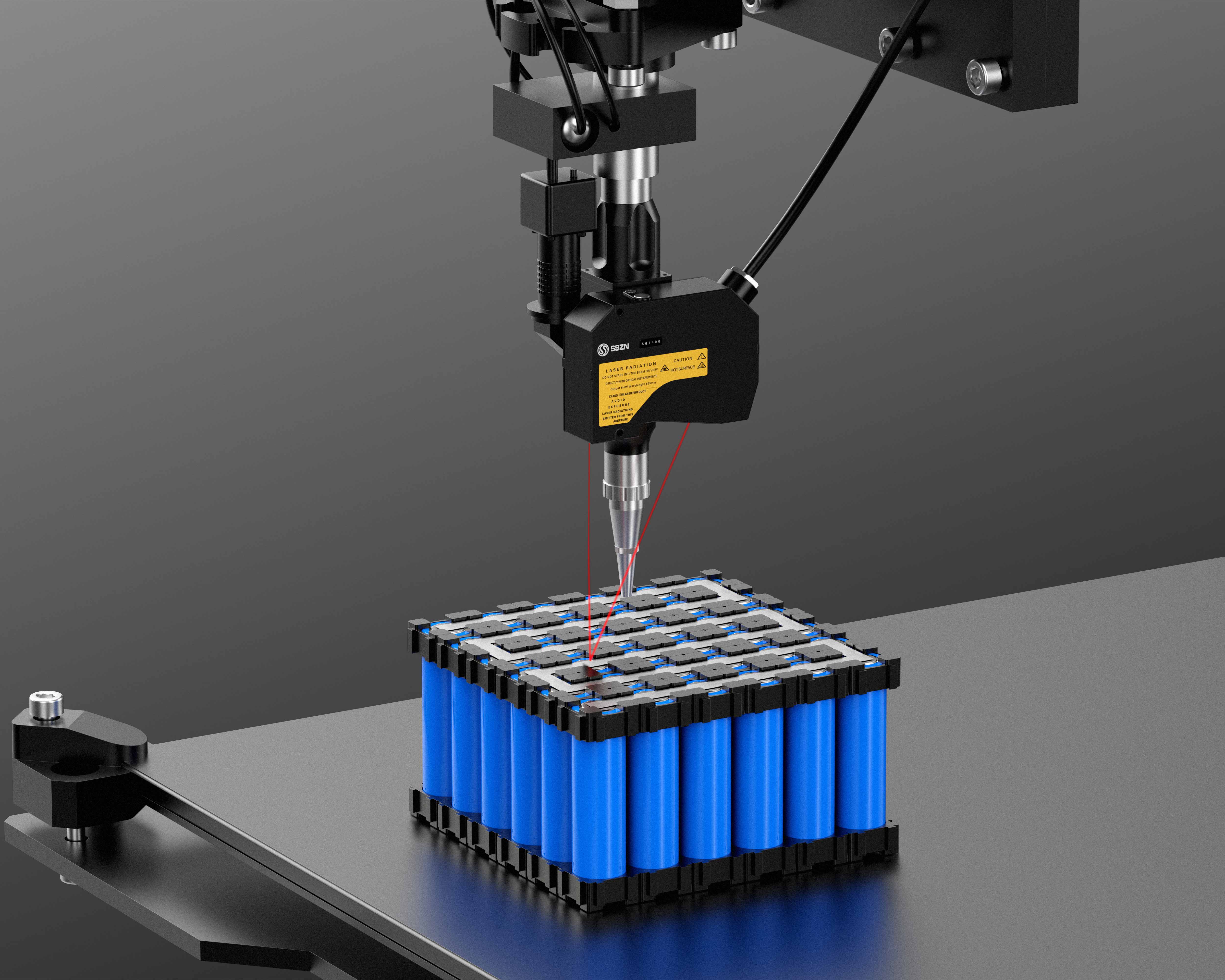

Applications

The SinceVision’s SG Series has become an indispensable tool across various industries such as Lithium battery, Film/resin/plate/plastic/rubber, Metal, Semiconductor, Electronic Components, Photovoltaics, Vehicle/transport. Its versatility and performance make it an essential part of automation and quality control processes.

1. Explosion-Proof Valve Testing

3. Sound System Vibration Detection

Explore more application here: SG Series

Why Choose SinceVision SGI Series?

SinceVision has been at the forefront of manufacturing innovation, consistently delivering products that push the boundaries of sensor technology. The SG Series exemplifies this approach, combining reliability with cutting-edge performance.

1. Increased Productivity: Ultra-fast sampling ensures reduced downtime and higher throughput.

2. Enhanced Quality Control: Advanced sensors detect even the smallest defects, ensuring consistently superior products.

3. Future-Ready Design: Seamless integration into existing systems paves the way for adopting automation solutions.

Image: SG Series Product Matrix

The Technology Behind the SG Series

The SG Series incorporates precision sensors and machine vision capabilities, making it ideal for tackling the demands of industrial automation. Here's why it’s a leader in the future of manufacturing:

a. Advanced Sensor Technology: Innovative laser displacement gauges handle tasks ranging from length measurement to multi-point displacement analysis.

b. Non-Contact and Contactless Sensors: Reduce wear and tear, leading to longer equipment life and higher reliability.

c. Smart Sensors and Automation Technology: Tailored for the industrial applications of tomorrow, the SG Series brings intelligence and precision to automation systems.

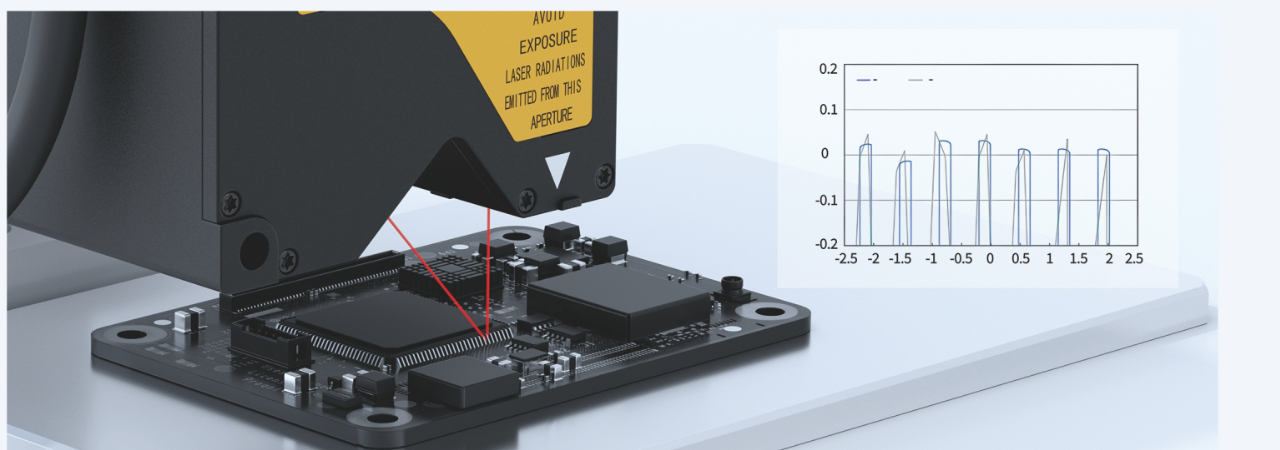

What Sets SG Laser Displacement Sensor Apart in Machine Vision?

Machine vision is a vital component of industrial automation. The SG Series integrates seamlessly with these systems, offering accurate data for smarter decision-making in real-time.

From inspecting component sizes to detecting structural flaws, the SG Series lays the groundwork for smarter, more connected factories.

At SinceVision, innovation is more than a buzzword; it’s the foundation of every product we create. With the SG Series Laser Displacement Sensors, we’re paving the way for a new era in automation technology, enabling industries to achieve unparalleled precision, speed, and reliability.

Conclusion

The SinceVision SG Series Laser Displacement Sensors are the cornerstone of industrial equipment innovation, offering unmatched speed, accuracy, and reliability. From automation technology to quality control, these sensors enable industries to stay ahead in a competitive market.

If your manufacturing process demands high precision and efficiency, it’s time to consider SinceVision's SG Series—because the future of manufacturing begins here.

For more information about our SG Series or to request a consultation, contact SinceVision.

-

Industry News2025-04-23SinceVision SR7400 Laser Profiler for Bowl Bottom Flatness Measurement

-

Industry News2025-04-23How SR7900 3D Laser Profiler Help to Detect Kinder Joy Egg Sealing?

-

Industry News2025-04-222000FPS High-Speed Camera Captures the Dynamics of Falling Droplets

-

Industry News2025-04-221000FPS High-Speed Camera Captures Bus Crash Test