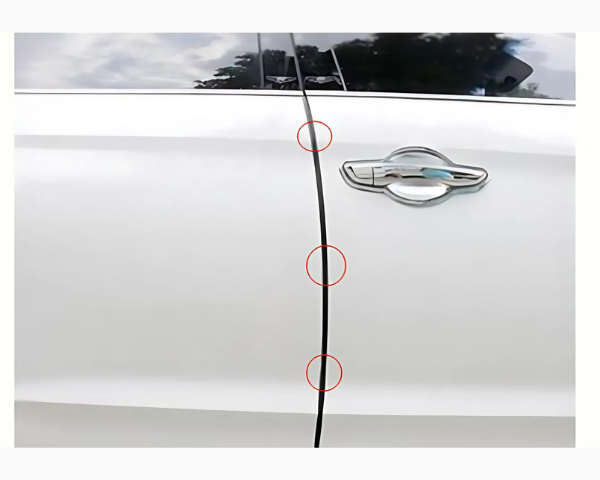

In the world of automotive manufacturing, the pursuit of perfection is relentless. No matter how small, every detail adds to a vehicle's quality and appeal. Door gaps are the spaces between a vehicle's doors and its body. They play a crucial role. It impacts weather sealing, noise reduction, structural strength, and quality.

The Critical Importance of Precise Door Gap Inspection

Why is precise door gap inspection so essential in car manufacturing? The answer lies in the confluence of functional requirements and customer expectations.

Aligning door gaps is key for the vehicle's best performance. Wide, narrow, or uneven gaps can hurt weather sealing. This can cause water leaks and wind noise. They can also contribute to structural weaknesses, affecting the vehicle's safety and longevity.

Door gaps matter for more than function. They have a significant impact on the appearance of a vehicle. Even gaps make things look better and more precise. They add to the sleek, high-quality appearance that customers want. Misaligned gaps can hurt a vehicle's look. They suggest bad craftsmanship and may upset customers. Misaligned door gaps can lead to more than bad looks. It can lead to costly recalls and warranty claims. They also damage a manufacturer's brand reputation.

In today's tough automotive market, quality matters. So, manufacturers must not ignore precise door gap inspections.

The Limitations of Traditional Measurement Methods

For many years, automotive manufacturers relied on traditional methods for measuring door gaps. These methods often can’t keep up with the stricter demands of today’s vehicle production.

qManual Gauges: Manual gauges, while simple, are time-consuming and prone to human error. They only give point-by-point measurements. This means they miss the shape and consistency of the gap.

q2D Vision Systems: 2D vision systems improve on manual methods. They still struggle with complex shapes and reflective surfaces in automotive manufacturing. They might struggle to meet the accuracy needed for today’s quality standards.

Traditional methods can't keep up with the fast pace of modern production lines. Rapid in-line inspection needs solutions that deliver accurate measurements. This must happen without slowing down production.

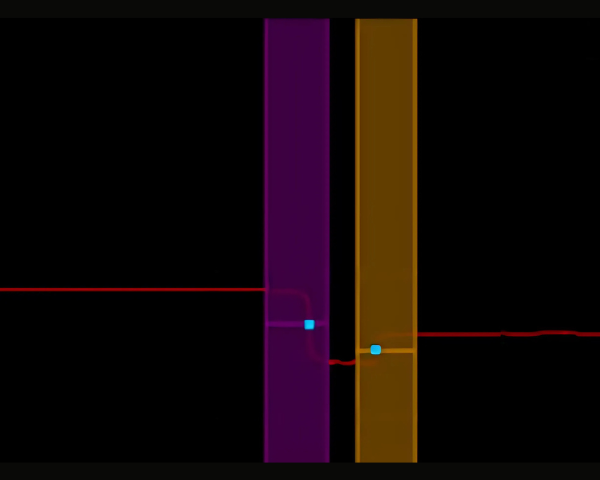

The Rise of 3D Laser Profilers: A New Era of Precision

Automotive manufacturers are moving away from traditional methods. They are now using advanced non-contact solutions like 3D laser profilers. These systems combine speed, accuracy, and versatility. This helps manufacturers reach new levels of precision in door gap inspection.

SinceVision is a leader in 3D laser profiler solutions for the automotive industry. Our SR7400 3D Laser Profiler is perfect for tough door gap checks on vehicle assembly lines.

Key Features and Benefits of the SinceVision SR7400

The SR7400 has many features that make it perfect for automotive manufacturers:

The SR7400 offers repeatability of 0.05 mm. This means it provides excellent accuracy in gap inspection. Manufacturers can meet tough quality standards with little effort. This level of precision translates to consistent, uniform door gaps across every vehicle.

The design of the SR7400 enables real-time analysis. It keeps up with the fastest production lines. This allows for in-line inspection. It cuts down on slow offline measurements and helps reduce production delays. The system boasts a scanning speed of up to 8000 Hz. The SR7400 can adapt to different automotive assembly lines. Its small size and strong design make it suitable for many installation setups.

The SR7400 collects a lot of data. It records 3,200 X-axis contour points. This gives a clear and detailed view of the door gap. This detail helps manufacturers spot even tiny differences from the design specs. The system has a linearity of ±0.05% F.S. (Full Scale) in the Z-axis (height). This means it provides consistent and reliable measurements throughout the full range.

The manufacturers designed the SR7400 to endure tough automotive manufacturing conditions. Its IP67-rated enclosure meets the IEC 60529 standard. This means it protects against dust and water, so it ensures reliable operation. The system achieves a Z-axis repetition accuracy of 5 μm. This ensures that measurements are consistent and dependable over time.

The system uses a 100Base-TX/1000Base-T Ethernet interface. The system works best when humidity is between 35% and 85%. It should not be condensing.

The Impact of Precise Door Gap Inspection on Vehicle Quality

The SinceVision SR7400 helps automotive manufacturers measure door gaps with precision and speed. This leads to significant improvements in vehicle quality.

qBetter Look: Even door gaps create a sleek, stylish appearance. This boosts customer satisfaction.

qImproved Function: Accurate gap control helps seal against weather. This cuts down on wind noise and stops water leaks.

qIncreased Durability and Safety: Well-aligned doors increase the vehicle's strength, enhancing durability and safety. This boosts safety and makes it last longer.

qFewer warranty claims and recalls: The SR7400 prevents defects. This helps manufacturers steer clear of warranty claims and costly recalls.

qStreamlined Production: Real-time, in-line inspection removes the need for slow offline measurements. This speeds up production and boosts efficiency.

Conclusion: Driving the Future of Automotive Manufacturing with Precision

The automotive industry is always changing. So, the need for precision and quality keeps growing. SinceVision's SR7400 3D Laser Profiler offers a strong solution for these needs. It helps manufacturers achieve perfect alignment of doors and enhance vehicle quality.

With advanced technologies like 3D laser profiling, car makers can shape the future. They can create vehicles with top performance, great looks, and strong reliability.

Please click here to learn more about the SinceVision SR7400 3D Laser Profiler and how it can revolutionize your vehicle assembly line. For demos or inquiries, please contact us.

-

Industry News2024-08-07Machine Vision: The Backbone of Semiconductor Manufacturing

-

Corporate News2024-12-12How 3D Laser Profilers Revolutionize Tire Inspection for the Automotive Industry

-

Corporate News2024-12-17Key Applications of 3D Laser Profilers in Automotive Manufacturing

-

Industry News2025-02-27Inspection of Chip Flatness with SinceVision SR9040 3D Laser Profiler

-

Industry News2025-03-05The Role of Step Height Detection in Watch Manufacturing with a Laser Displacement Sensor

-

Corporate News2025-03-25Safeguarding Food Safety: How SinceVision's 3D Packaging Inspection Transforms the Industry