SinceVision is proud to announce the release of its new strategic product: the SRI Series All-in-One Laser 3D Profile Measurement Device!

With a comprehensive upgrade in industrial design, the SRI Series enhances versatility, usability, and cost-effectiveness, driving the transition from 2D to 3D machine vision. This innovation promotes the adoption of high-precision 3D measurement technology, offering robust support for industrial upgrades and the rapid development of intelligent manufacturing across multiple sectors.

Comprehensive Hardware Upgrades

1. Highly Integrated Hardware

Image: 3D laser profiling SRI series

The 3D Laser Profiler SRI Series integrates the sensor head and controller into a single system, increasing space efficiency by 65% and enabling seamless integration with industrial machinery. With an IP67 dust- and water-resistant rating and a highly compact internal structure, the device operates reliably even in harsh environments.

2. Multi-Wavelength Laser Options

Image: Multi-wave length options of SRI 3D laser profiler

The SRI Series offers a choice of blue, red, or green laser wavelengths, reducing interference in multi-camera setups with overlapping wavelengths. It enhances measurement accuracy in multi-camera stitching projects and effectively tackles challenges like outdoor light interference and imaging low-reflectivity, black materials in complex environments.

3. Expanded Product Range

Building on the 3D Laser Profiler SR Series, the SRI Series introduces the SRI7700 and SRI72800, designed for large field-of-view applications. Covering a range from 14mm to 3m, the series achieves breakthroughs in key metrics, including a 3.5x increase in Z-axis field of view and a frame rate of 20kHz, meeting the rigorous demands of various application scenarios for field-of-view, precision, and speed.

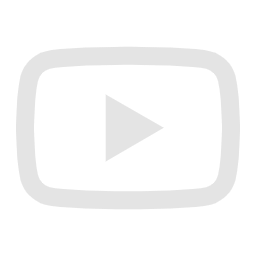

4. Reduced Temperature Drift

Image: 3D laser profiling has superior temperature drift suppression to reduce accuracy loss

The 3D Laser Profiler SRI Series improves temperature drift suppression by 50%, minimizing accuracy loss caused by environmental temperature fluctuations. This makes it ideal for dual-camera thickness measurements and multi-camera stitching applications.

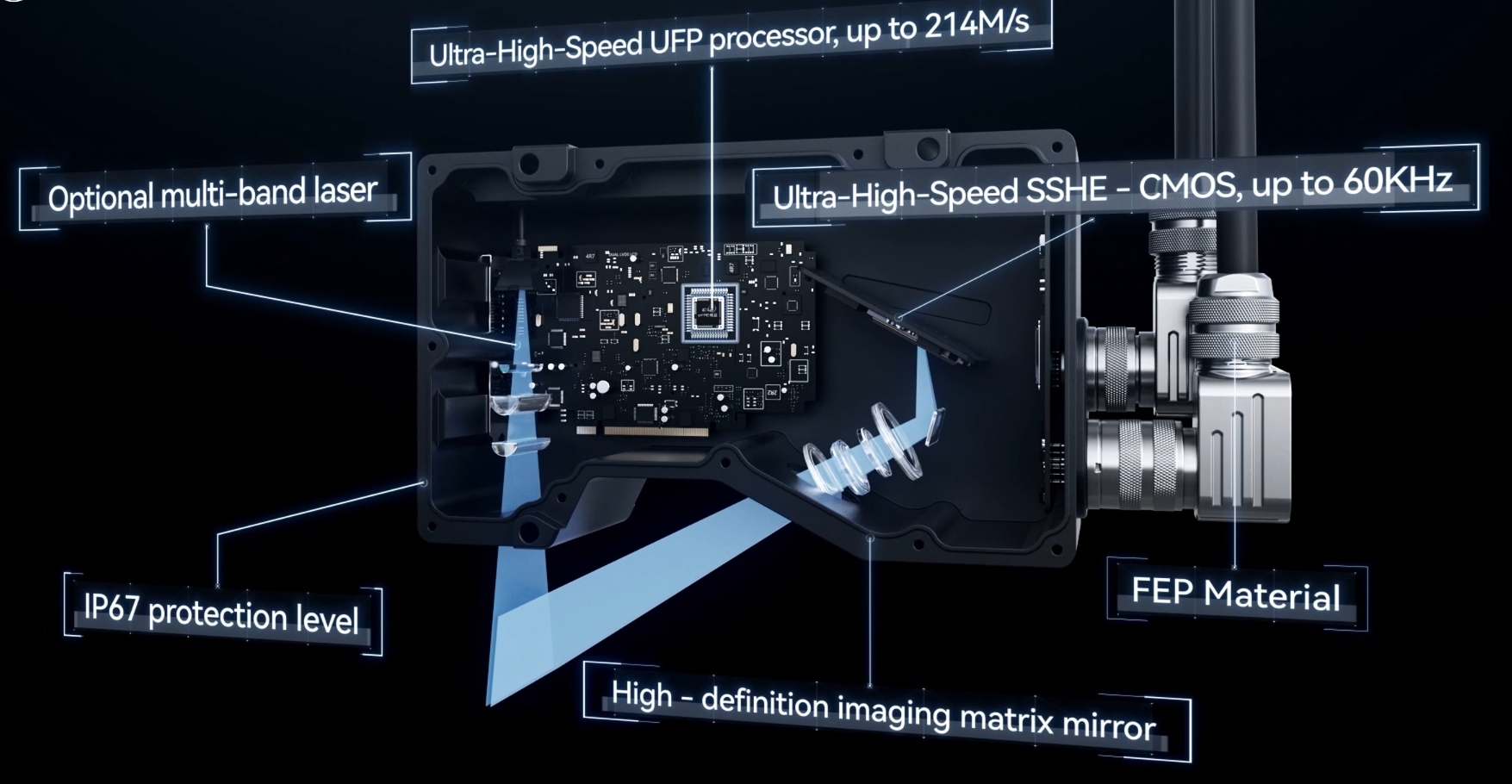

5. Enhanced Connectors

Image: Features of 3D laser profiler

The cables now feature high-performance FEP material, upgraded connectors, and a suspended structural design, significantly improving resistance to vibration, stretching, and interference. These enhancements ensure reliable operation in diverse industrial environments.

6. Optimized Grayscale Algorithm

To meet market demand for AI-driven inspection applications, the SRI Series features a fully upgraded grayscale algorithm. By adopting high-contrast 8-bit grayscale images and introducing 8-bit width maps, it captures intricate details across materials with varying reflectivity.

Leading Innovation, Driving Efficiency

With outstanding performance and cost-effectiveness, the 3D Laser Profiler SRI Series marks a new milestone for SinceVision in the field of 3D measurement technology. It provides customers with more options while advancing the localization and widespread application of high-end industrial sensors.

Looking forward, we remain committed to expanding our product lineup and contributing to the transformation and upgrading of various industries.

-

Industry News2025-04-23SinceVision SR7400 Laser Profiler for Bowl Bottom Flatness Measurement

-

Industry News2025-04-23How SR7900 3D Laser Profiler Help to Detect Kinder Joy Egg Sealing?

-

Industry News2025-04-222000FPS High-Speed Camera Captures the Dynamics of Falling Droplets

-

Industry News2025-04-221000FPS High-Speed Camera Captures Bus Crash Test