Measurement of Bowl Bottom Flatness in the Food and Packaging Industry

In the food and packaging industry, maintaining the dimensional integrity of containers, particularly the flatness of bowl bottoms, is of paramount importance. Consistent bowl bottom flatness is essential to ensure proper sealing, stable stacking, and accurate filling processes.

Deviations from flatness can lead to a cascade of problems, including compromised package integrity, spillage of contents, and inefficiencies in automated handling systems. Consequently, the industry faces the ongoing challenge of implementing reliable and high-precision methods for measuring and controlling bowl bottom flatness in high-volume production environments.

2. Problems in Measurement of Bowl Bottom Flatness

Traditional inspection methods often struggle to meet the demands of modern food and packaging production. Key challenges include:

a. Lack of Precision: Conventional contact-based measurement techniques can lack the required precision to detect subtle variations in flatness, potentially leading to undetected defects.

b. Slow Measurement Speed: Traditional methods can be time-consuming, creating bottlenecks in high-speed production lines and hindering overall throughput.

c. Destructive Testing: Some techniques involve destructive testing, which is not feasible for continuous, inline quality control.

d. Inconsistent Results: Variability in manual inspection or contact-based methods can lead to inconsistent results and subjective assessments.

These issues highlight the need for advanced non-contact inspection solutions that can provide accurate, rapid, and reliable measurements of bowl bottom flatness.

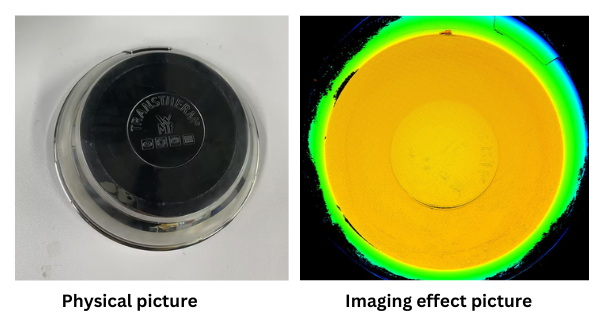

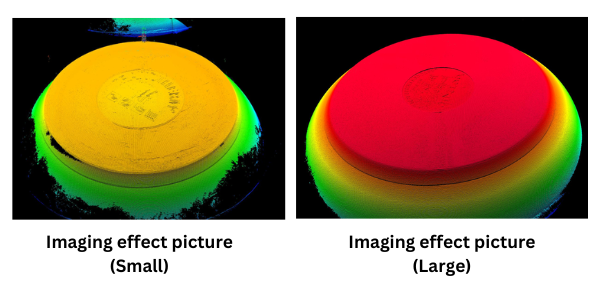

3. Solution: SinceVision SR7400 3D Laser Profiler

SinceVision addresses these challenges with the SR7400 3D Laser Profiler, a non-contact measurement system designed to deliver precise and efficient flatness inspection.

The SinceVision SR7400 3D Laser Profiler offers the following key features:

1. High-Accuracy Inspection: The SR7400 measures flatness deviations with exceptional precision, ensuring optimal performance in subsequent sealing and stacking processes.

2. Real-Time Analysis: The profiler enables immediate detection of defects, allowing for prompt corrective action, minimizing downtime, and reducing production delays.

3. Seamless Integration: The SR7400 is designed for easy integration into existing food and packaging production lines, facilitating streamlined quality control workflows.

Technical Specifications:

i. Reference distance (CD): 400mm

ii. Repetition accuracy Z-axis (height): 5μm

iii. Linearity Z-axis (height): ±0.05% F.S.

iv. X-axis contour points: 3200

v. Scanning speed (Hz): Up to 8000

vi. Degrees of protection provided by enclosure: IP67, in accordance with IEC 60529 standard

vii. Operation Temperature: 0~50℃

By implementing the SR7400, manufacturers can achieve a higher degree of control over bowl bottom flatness, leading to improved product quality, reduced waste, and increased production efficiency.

4. Conclusion

The SinceVision SR7400 3D Laser Profiler provides a robust and effective solution for the challenges associated with measuring bowl bottom flatness in the food and packaging industry. By enabling high-accuracy, real-time, and seamlessly integrated inspection, the SR7400 empowers manufacturers to ensure consistent container quality, optimize production processes, and minimize the risk of defects.

Explore more on SR7400 and contact us for sales/sample/demo.

-

Industry News2025-09-30Precision in Power Electronics: SinceVision SR8060 3D Laser Profiler for IGBT Heat Dissipation Module Inspection

-

Corporate News2025-09-24SinceVision Strengthens Global Reach with Supportive Membership in Japan Industrial Imaging Association (JIIA)

-

Industry News2025-09-29SinceVision to Showcase Industrial Vision Sensors at SPS Germany 2025 Machine Vision Exhibition

-

Industry News2025-09-02Case Study: How SinceVision's Integrated 3D Laser Profiler Solves Precision Measurement Challenges in Foldable Screen Hinges