Sealing Detection in Food Packaging

Ensuring the integrity of packaging seals is a critical aspect of quality control within the food industry. Proper sealing is paramount to maintain product freshness, prevent contamination, and uphold consumer trust. Defective seals can lead to product spoilage, ingress of harmful substances, and ultimately, a negative impact on brand reputation. As production lines become increasingly automated and operate at higher speeds, the challenge of reliable and efficient sealing detection has grown. The industry faces the need for inspection solutions that can keep pace with production demands while maintaining the highest levels of accuracy and adaptability.

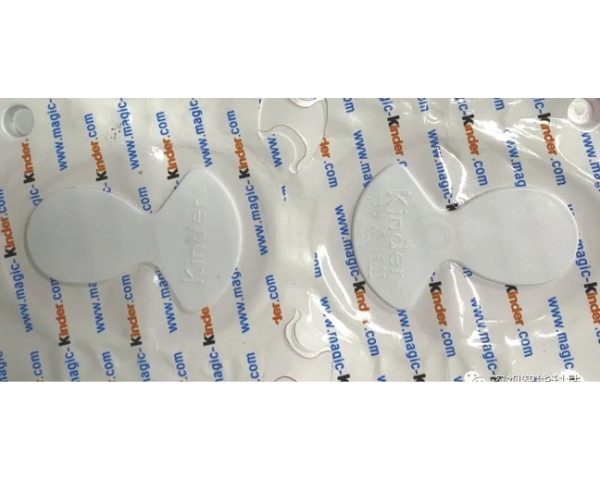

Problems in Sealing Detection of Kinder Joy Eggs

The unique shape and packaging of Kinder Joy eggs present specific challenges to traditional sealing detection methods. These challenges include:

a. Complex Geometry: The non-uniform shape of the Kinder Joy egg makes it difficult for conventional sensors to achieve consistent and accurate seal inspection.

b. Material Variation: The diverse materials used in the packaging, including plastics and foils, can exhibit varying reflective properties, further complicating the detection process.

c. High-Speed Production: The rapid pace of Kinder Joy egg production lines demands inspection systems capable of processing a high volume of products without compromising accuracy.

These factors contribute to the potential for irregular or faulty seals, which can compromise product safety and quality.

Solutions: SinceVision SR7900 3D Laser Profiler

SinceVision addresses these challenges with the SR7900 3D Laser Profiler, a solution designed to provide precise and reliable sealing detection for complex packaging formats.

The SinceVision 3D Laser Profiler offers the following key features:

1. Precise Seal Inspection: The SR7900 accurately detects sealing defects such as gaps, misalignments, or weak points, effectively preventing contamination and spoilage.

2. Adaptable Design: The profiler's design is versatile, enabling it to handle the unique shapes and varying packaging materials of Kinder Joy eggs.

3. Real-Time Quality Control: The SR7900 operates efficiently on high-speed production lines, providing instant feedback to minimize waste and ensure product safety.

Technical Specifications:

X-axis contour points: 3200

Scanning speed (Hz): Up to 8000

Linearity Z-axis (height): ±0.05% F.S.

Reference distance (CD): 900mm

By employing the SR7900, manufacturers can achieve a higher level of quality control, ensuring that every Kinder Joy egg meets the stringent standards required for product integrity and consumer safety.

Conclusion

The SinceVision SR7900 3D Laser Profiler provides a robust and effective solution for the challenges associated with sealing detection in the production of uniquely shaped products like Kinder Joy eggs. By offering precise inspection, adaptable design, and real-time quality control, the SR7900 empowers manufacturers to maintain product freshness, ensure consumer safety, and uphold brand reputation in the competitive food industry.

Explore more on SR7900 and contact us for sales/sample/demo.

-

Industry News2025-09-30Precision in Power Electronics: SinceVision SR8060 3D Laser Profiler for IGBT Heat Dissipation Module Inspection

-

Corporate News2025-09-24SinceVision Strengthens Global Reach with Supportive Membership in Japan Industrial Imaging Association (JIIA)

-

Industry News2025-09-29SinceVision to Showcase Industrial Vision Sensors at SPS Germany 2025 Machine Vision Exhibition

-

Industry News2025-09-02Case Study: How SinceVision's Integrated 3D Laser Profiler Solves Precision Measurement Challenges in Foldable Screen Hinges