Smartphone Middle Bezel & Frame Flatness Inspection with 3D Laser Profiler

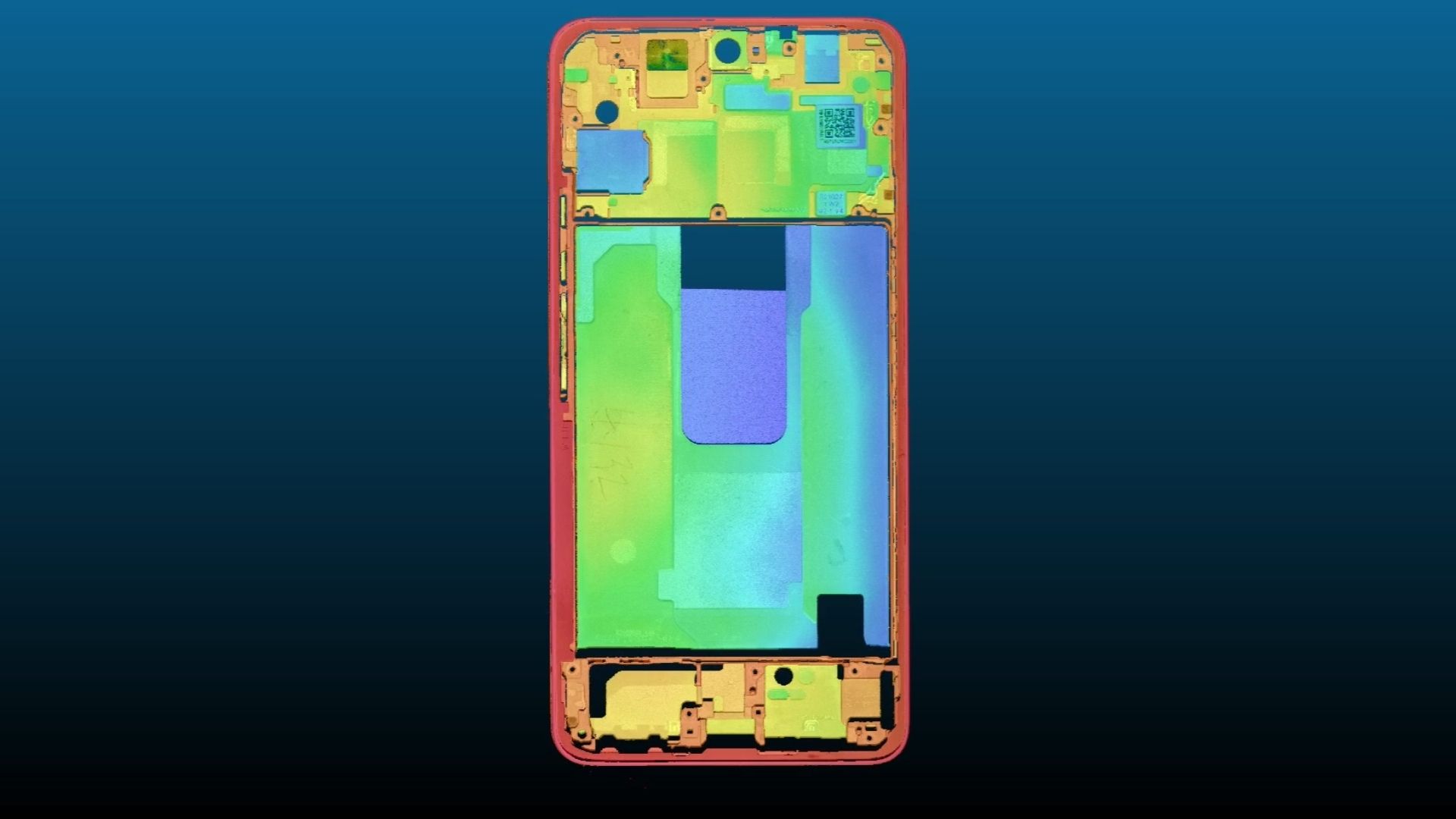

In the consumer electronics industry, particularly in smartphone manufacturing, the flatness of the smartphone frame is a critical quality metric. Frame flatness not only affects the aesthetic appeal of the device but also plays a significant role in ensuring proper assembly and functionality.

Any deviations in flatness can lead to issues such as improper fitment of components, decreased structural integrity, and compromised user experience. Therefore, manufacturers face the challenge of efficiently and accurately measuring frame flatness to ensure that only frames meeting stringent quality standards proceed to assembly.

SinceVision Solutions: SRI7140 3D Laser Profiler

Camera Selection

| Model number | SRI7140 | |||

| Reference distance (CD) | 140mm | |||

| Measuring range | Z-axis height (FS) | +34mm, -54mm (FS=88mm) | ||

| X-axis width | Near side | 70mm | ||

| Reference distance | 86mm | |||

| Remote side | 110mm | |||

| Light source | Light source wavelength | 405nm | ||

| Laser class | 2M | |||

| Laser output power | 10mW | |||

| Repetition accuracy | Z-axis (height) | 0.5μm | ||

| X-axis (width) | 7.5μm | |||

| linearity | Z-axis (height) | ±0.02% of F.S. | ||

| Contour data interval | X-axis (width) | 30μm | ||

| X-axis contour points | 3200 | |||

| Scanning speed (Hz) | 1500-20000Hz | |||

| Dimension (mm) | 155.5 x 54 x 94.5mm | |||

| Weight (g) | 1000 | |||

| Temperature characteristic | 0.01% F.S./℃ | |||

| Encoder input | Differential encoder (trigger)④, start signal⑤ | |||

| Input/output | One 100Base-TX/1000Base-T Ethernet interface | |||

| Operation Temperature | 0~50℃ | |||

| Storage Temperature | -20~70℃ | |||

| Working Humidity | 35% to 85% without condensation | |||

| ESD Protection | Contact discharge 4kV, air discharge 8kV, in accordance with IEC 61000-4-2 standards | |||

| EFT protection | Power port 2kV/5 or 100kHz, signal port 1kV/5 or 100kHz, in accordance with IEC 61000-4-4 standards | |||

| Impact | 15Gs/6ms per axis, in accordance with IEC 68-2-27 Ea standard | |||

| Vibration | (10-150Hz), compliant with IEC 68-2-6 Fc standard | |||

| degrees of protection provided by enclosure | IP67, in accordance with IEC 60529 standard | |||

| Data cable (network cable) model | Type L: SCB-HNET-HR2Z-3m/6m/10m Type I: SCB-HNET-HB2Z-3m/6m/10m | |||

| Data cable (IO cable) model | Type L: SCB-HIO-HR2Z-3m/6m/10m Type I: SCB-HIO-HB2Z-3m/6m/10m | |||