Enhancing PCB Quality Control with SinceVision's Spectral Confocal Displacement Sensors

Industry pain points and demands

The complex nature of modern PCBs, coupled with strict quality standards in the electronics industry, necessitates precise inspection techniques. Traditional methods often fall short in detecting subtle defects and variations, potentially leading to product failures.

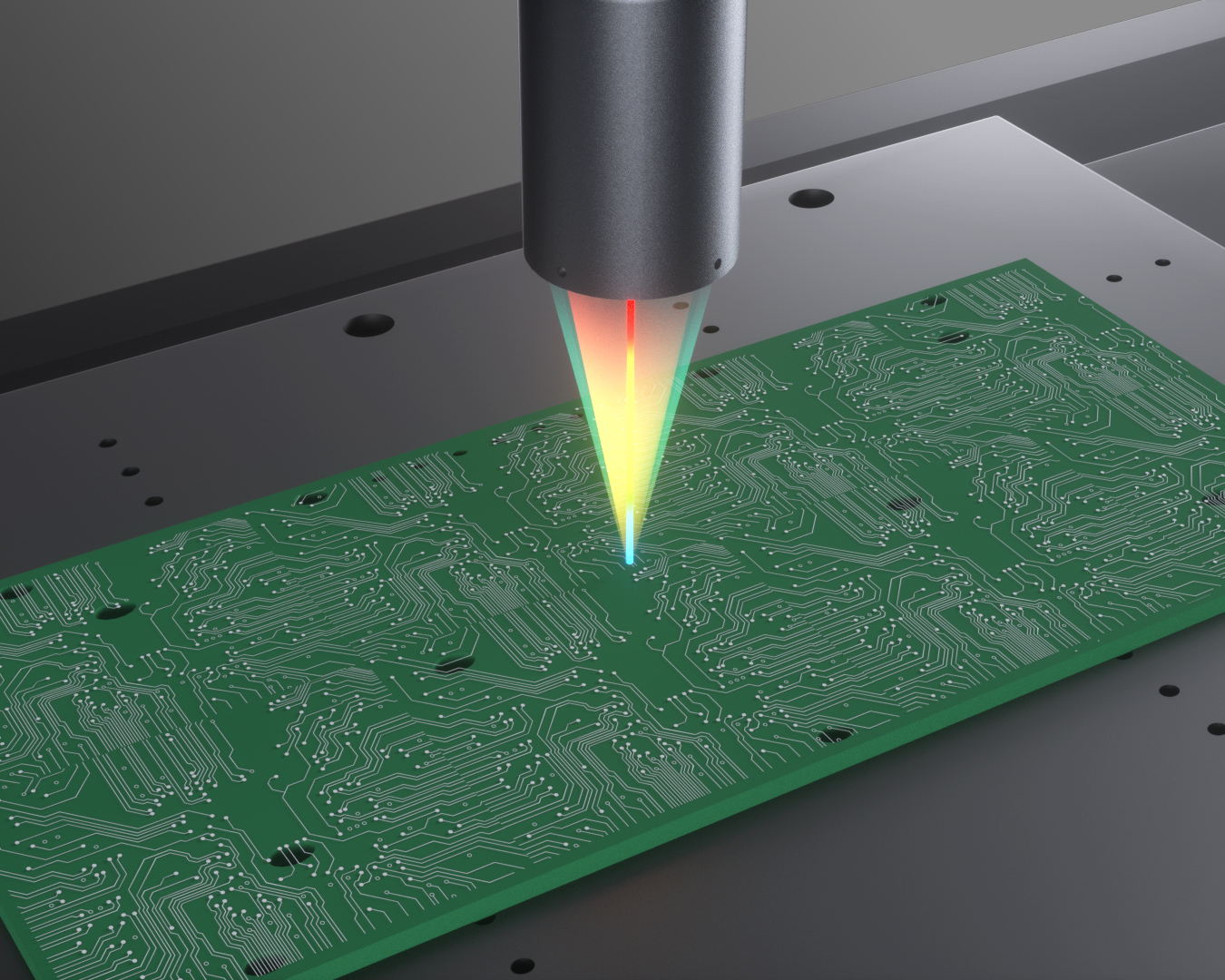

SinceVision's Spectral Confocal Displacement Sensor addresses these challenges by enabling accurate measurement of critical parameters such as PCB flatness, thickness, solder joint integrity, and component placement. This advanced technology empowers manufacturers to ensure product quality, reduce defects, and optimize production processes.

SinceVision Solution: SC03560 Spectral Confocal Displacement Sensor

01SinceVision's Spectral Confocal Displacement Sensor offers a comprehensive solution for precise measurement in demanding applications. With a wide measurement range of ±60 degrees, ultra-high linearity, and a minimum spot size of 5.8μm, this advanced sensor delivers exceptional accuracy and precision.

02Non-contact measurement capabilities ensure damage-free inspection, while real-time monitoring enables continuous process optimization.

03By seamlessly integrating our sensors into existing production lines, this sensor empowers manufacturers to achieve optimal quality control and improve overall efficiency.

Camera Selection

| Model number | SC03560 | |

| controller | SC5001A / SC5002A | SC5001B / SC5002B |

| Optical fiber jumper | 50μm / 125μm | 105μm / 125μm |

| Spot size | 5.8 mu m | 12.2 mu m |

| Measuring range | The 3.5 mm | |

| Angle characteristic | Plus or minus 60 ° | |

| Numerical aperture | 0.866 | |

| Working distance | The 12.8 mm | |

| Axial resolution | 0.006 mu m | |

| straightness | ±0.01% F.S | |

| Minimum measurable thickness of transparent object | 150 microns | |

| diameter | 83mm | |

| length | 257mm | |

| weight | 2300g | |