1. Experimental Background

Composite materials are changing industries like aerospace and new energy. They are lightweight and strong, making them very beneficial. In materials science, researchers often struggle with brittle fracture. This issue arises during tensile testing of composite materials. This experiment uses high-speed cameras and Digital Image Correlation (DIC) methods. It creates a precise sequence for tracking image motion [1].

Using a high-speed camera, we capture images of a composite material as it fractures. Then, we input these images into DIC software for detailed analysis. This process allows us to obtain the precise pixel coordinates of target points. As a result, we can track the moving targets with complete accuracy. This helps us understand the complex behavior of composite materials.

2. The Ingenious Combination of High-Speed Cameras and DIC Technology

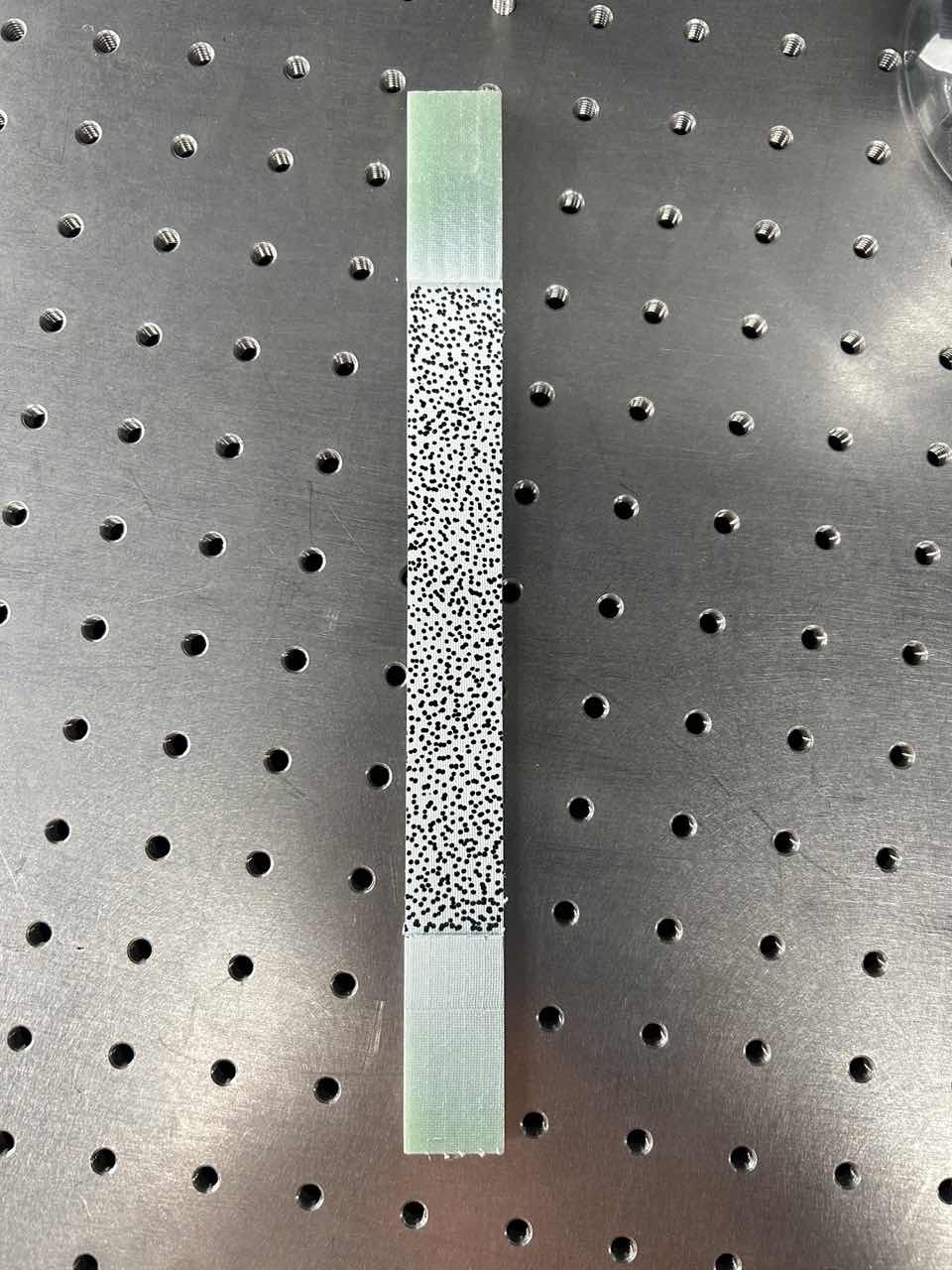

We sprayed matte white paint on composite materials. This created a smooth white background for better image analysis of speckle patterns.

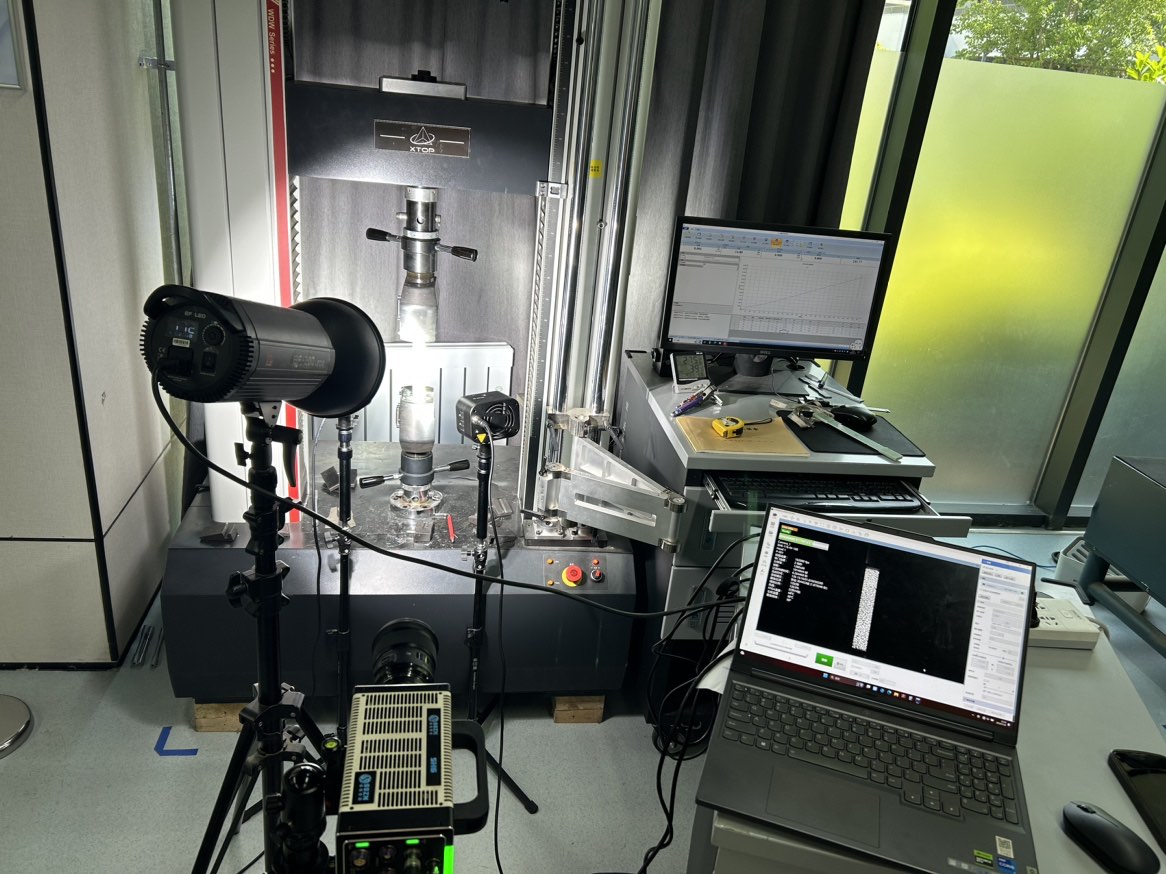

SinceVision’s ultra-high-speed camera series captures speckle images of composite materials under load. It has a resolution of 1280×88 and a frame rate of 160,000 FPS. This allows for quick and precise images of different deformation stages. This provides a rich and accurate data foundation for later analysis.

Image: Observation of Composite Material Tensile Testing

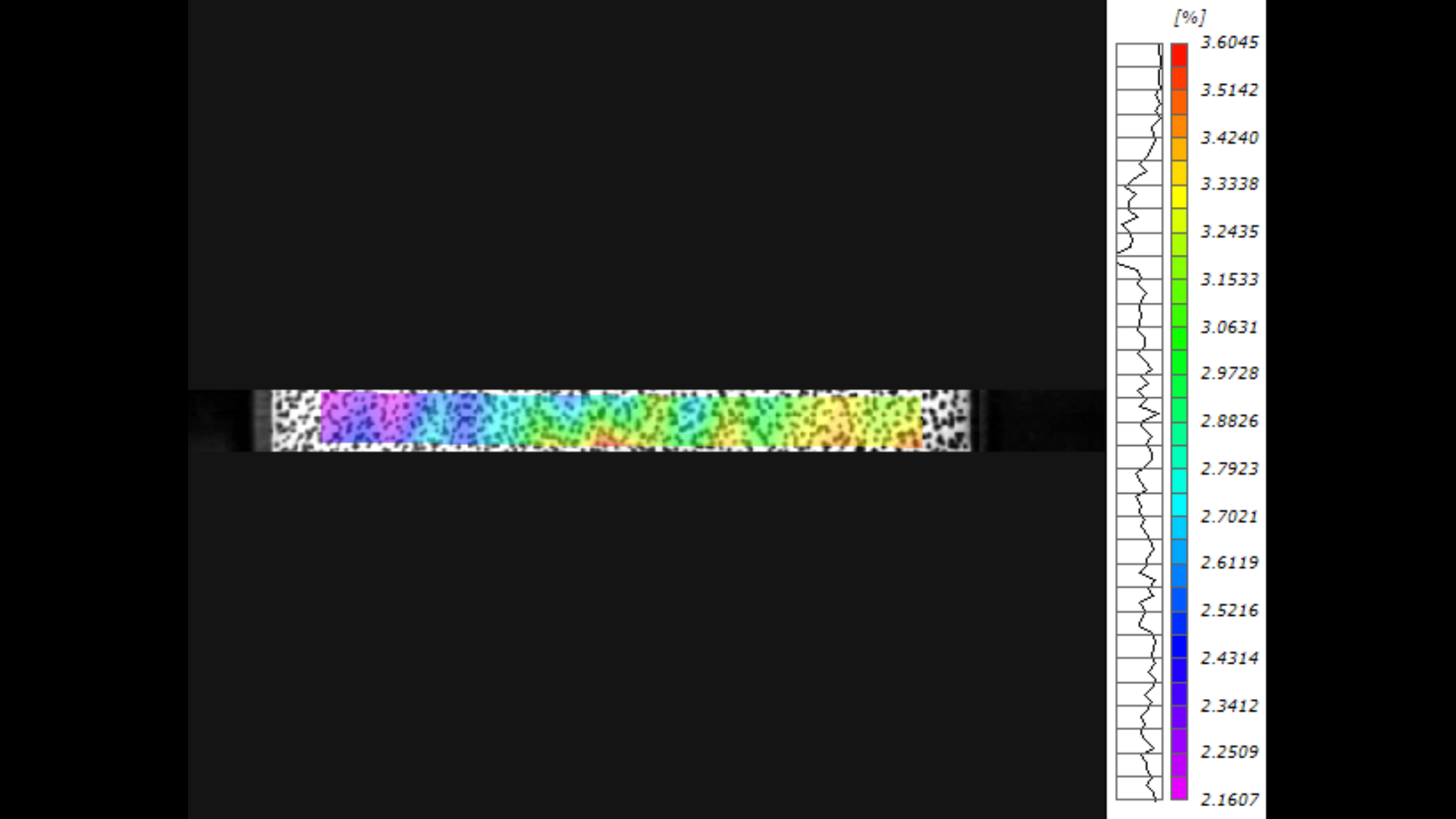

After uploading the composite material images from the high-speed camera into DIC software, the Digital Image Correlation algorithm then matches and analyzes the speckle images from different times on the material's surface. Tracking marker points gives us data on displacement and deformation of the composite material's surface.

Image: Speckle Images Captured by High-Speed Camera

This method boosts measurement accuracy and efficiency. It also offers better data for studying the mechanical properties of composite materials. This helps us understand how they deform and fail under stress.

3. Advancing Materials Science Development

The advantages of high-speed cameras in composite material tensile testing are evident. Their high frame rate and fast capture let us see changes in composite materials when they are under tension. This lets us quickly check compatibility and conditions. It shows their feasibility and benefits. This is very important for materials science research and creating new products.

SinceVision’s Ultra-High-Speed Camera SH6-116 revolutionizes industrial applications with its 1280x1024 resolution for detailed analysis, 14.6μm pixel size, and 100ns shutter speed for precise high-speed imaging. Offering 15800fps full frame rate and 11575fps maximum frame rate, plus ≥210ns PIV exposure, it excels in capturing critical moments. Equipped with an ISP image processing unit, 24TB maximum bandwidth for high-speed data storage, and features like PRNU correction, built-in large-capacity storage, a graphical interface, and SDK support, the compact 217Dx110Wx110H mm camera is ideal for industrial automation and quality control.

Please visit the product page for more information. For sales inquiries, visit our contact page.

References:

[1] Mei Huafeng, Chen Peng, Tong Xiaohua, et al. Rapid Tracking of Motion Targets in High-Speed Camera Sequence Images Using Digital Image Correlation Methods [J]. Geo-Information World, 2013, 20(05):51-58

-

Corporate News2024-10-17High-Speed Imaging for Hydrodynamics: A Closer Look

-

Corporate News2024-12-12The All-New SinceVision Smart Series High-Speed Camera: Precision, Innovation, and Ultra Performance

-

Corporate News2024-12-24Observing Bacterial Flagella Motion with MINI Series High-Speed Cameras

-

Corporate News2025-01-22The Ultimate Guide to Smart Series High-Speed Cameras for Industrial and Scientific Applications