Medical glass bottles, like ampoules, vials, and infusion containers, are key players in keeping medicines safe and effective. These containers protect drugs from contamination and maintain their stability. However, a crucial part of their safety depends on their thickness. If the glass is too thin in some spots, it could break or fail to protect the medication.

Let’s explore how SinceVision’s SCI Series Spectral Confocal Displacement Sensors make measuring bottle thickness easy, accurate, and efficient.

The Challenge: Why Bottle Thickness Matters

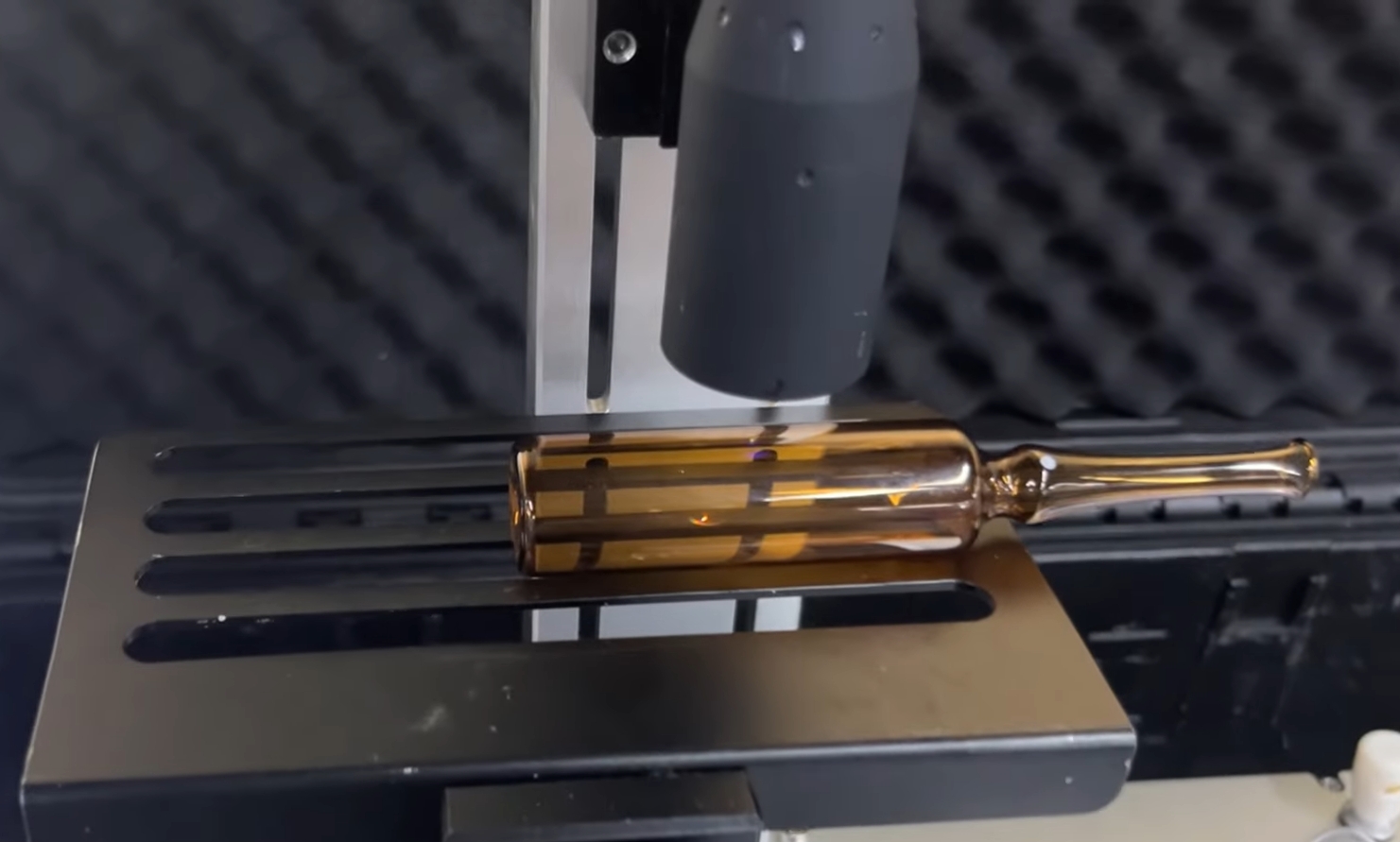

Image: Measuring Medical Glass Bottle Thickness with SCI Series Spectral Confocal Displacement Sensors

Glass bottles used in medicine must be thick enough to hold up during transportation, storage, and usage. When thickness is inconsistent, it can lead to:

a. Cracks or Breakage: Fragile spots in the glass can cause bottles to crack, leading to wasted medication and potential accidents.

b. Contamination Risks: If a bottle fails, medicine could be exposed to contaminants, affecting its safety and effectiveness.

c. Production Delays and Costs: Discovering flaws late in production wastes time and materials, driving up costs.

Measuring thickness across every part of the bottle is vital but it’s a tricky task because of the smooth, clear surfaces of glass.

The Solution: SCI Series Spectral Confocal Displacement Sensors

SinceVision’s SCI Series Spectral Confocal Displacement Sensors are designed to tackle these challenges with advanced, non-contact technology that ensures precise thickness measurements, even on transparent materials. Here’s how they help manufacturers improve quality:

Parameters:

Model: SCI04025

Measurement method: single head

Angle characteristic: ±25°

Spot size: 12μm

1. Accurate Measurement: The SCI Series sensors can measure the thickness of transparent glass down to microns (a fraction of a hair strand!). This ensures bottles meet quality standards every time.

2. Real-Time Detection: With the SCI Series, manufacturers can spot defects or inconsistencies in thickness instantly. This means no waiting or delays in addressing problems.

3. Quality Assurance: These sensors ensure the bottles are thick enough to protect medications effectively. By safeguarding glass container quality, they also protect patients' safety.

4. Enhanced Efficiency: The SCI Series streamlines production by identifying issues quickly, reducing material waste, and saving money in the long run.

How the SCI Series Spectral Confocal Displacement Sensors Works

Using spectral confocal displacement technology, these sensors focus a light beam through the glass to measure thickness without ever touching the bottle. This non-contact method works perfectly on the clear, curved surfaces of medical bottles, ensuring:

· No scratches or damage to the product during inspection.

· Consistently reliable results, even on complex shapes.

Why Choose SinceVision’s SCI Series?

Image: SCI04025 Spectral Confocal Displacement Sensors

a. Industry-Leading Precision: Perfect for demanding applications in the medical field.

b. Durable and Reliable: Built for non-stop performance in high-production environments.

c. Easy Integration: Fits seamlessly into production lines without slowing down operations.

Transforming Medical Glass Bottle Production

SinceVision’s SCI Series sensors are an essential tool for manufacturers looking to raise their standards for safety and efficiency. By ensuring every glass bottle meets exact thickness requirements, the SCI Series helps the medical industry deliver quality and reliability to patients worldwide.

If you’re looking for a solution that combines cutting-edge technology with proven results, SinceVision’s SCI Series Spectral Confocal Displacement Sensors are the clear choice. Ready to improve your production process? Contact us today!

-

Corporate News2025-01-23Application Case | Height Guidance for Blind Hole Dispensing on Smartphone Screens with SinceVision SG Series Laser Displacement Sensor

-

Corporate News2025-01-23SinceVision to Showcase Cutting-Edge High-Speed Cameras at Asia Photonics Expo (APE) 2025

-

Corporate News2025-01-22The Ultimate Guide to Smart Series High-Speed Cameras for Industrial and Scientific Applications

-

Industry News2025-01-13From Smart Homes to LiDAR: The Most Advanced Sensors at CES 2025