Accurate food counting is a cornerstone of the food and packaging industry, ensuring efficient portioning, reducing waste, and adhering to strict quality standards. Despite its importance, traditional counting methods often falter when faced with irregularly shaped items, varying sizes, and the rapid pace of modern production lines. This inefficiency can lead to costly errors and hinder operational productivity. Recognizing these challenges, SinceVision introduces the SR7900 3D Laser Profiler—a state-of-the-art solution poised to redefine the standards of precision and efficiency in food counting.

The Problem with Traditional Food Counting

Food and packaging industries rely heavily on accurate counting for production efficiency, quality assurance, and customer satisfaction. Conventional methods, whether manual or semi-automated, struggle with the inherent unpredictability of food items. Irregular shapes, inconsistent sizes, and the need for real-time processing create hurdles that traditional systems cannot effectively overcome. These shortcomings often result in miscounts, overfilling or underfilling of packages, and wasted resources. Additionally, maintaining hygiene standards in manual operations can pose further challenges, risking contamination and compromising product integrity.

The Solution: Advanced 3D Laser Profiling

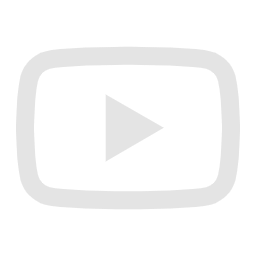

Image: Fried Chicken Counting Captured by SinceVision's SR7900 3D Laser Profiler

The SinceVision SR7900 3D Laser Profiler offers a comprehensive solution tailored for the dynamic needs of food counting. Utilizing cutting-edge 3D camera and laser profiler technology, this device ensures precise counting, superior hygiene compliance, and seamless adaptability for diverse applications.

The adaptable matrix design of the SR7900 allows it to accommodate food items of various shapes, sizes, and configurations. Whether it’s small cylindrical candies, irregularly shaped baked goods, or larger produce items, this system ensures unmatched accuracy. With a high-speed scanning capability of up to 8000 Hz, it can process numerous items in real time, keeping up with the demands of fast-paced production lines. Furthermore, its non-contact inspection feature not only guarantees hygienic operations but also prevents potential damage to delicate items, ensuring optimal product integrity.

SR7900 3D Laser Profiler Key Features

Image: SinceVision's SR7900 3D Laser Profiler

· Impressive Adaptability: The SR7900 3D laser profiler handles diverse item configurations effortlessly, making it ideal for bulk sorting, packaged goods, and quality assurance applications.

· High-Speed Detection: With advanced scanning speeds, it maintains efficiency without compromising accuracy.

· Hygiene-Focused Design: By eliminating contact during inspection, it ensures compliance with the highest food safety standards.

· Technical Superiority:

o X-axis contour points: 3200

o Reflection angle: 13°

o Repetition accuracy (Z-axis: 12μm, X-axis: 40μm)

o Operating temperature: Up to 50°C

Applications of 3D Laser Profiling in Food Industries

The versatility of the SR7900 extends to a range of food counting tasks. For instance, it excels in packaged goods counting, ensuring accurate quantities in pre-packaged snacks or candies. For batch sorting, the system distinguishes individual items, facilitating precise portioning. Additionally, in quality assurance, the laser profilometer detects even minor irregularities, ensuring strict compliance with industry regulations and customer expectations.

Why 3D Cameras Enhance Precision

The integration of a 3D camera enhances the SR7900’s ability to provide precise depth and contour analysis. This enables the system to handle items with intricate surfaces or variable thickness, ensuring accurate surface profile measurement and count. By combining laser scanning with high-resolution imaging, the 3D laser profiler bridges the gap between speed and precision in industrial applications.

While designed for food counting, the SinceVision SR7900 3D Laser Profiler proves its versatility across industries. Its robust engineering aligns it with other industrial tasks, positioning it as an industrial 3D scanner for broader applications, including construction and semiconductor manufacturing. Recognized as one of the best 3D scanners for construction, it adapts seamlessly to diverse environments, handling everything from precision measurement to fault detection.

The SR7900 3D Laser Profiler symbolizes SinceVision’s commitment to innovation and excellence. By addressing critical challenges in food counting with a focus on speed, hygiene, and precision, this advanced system transforms operational workflows and sets new industry standards. If you’re ready to elevate your production line and maintain uncompromised quality, SinceVision’s 3D laser profiling solutions are here to guide you toward success.

Visit SinceVision today to explore how we can empower your business with cutting-edge technology. Together, let’s shape a future defined by precision and productivity.

-

Industry News2025-04-17How High-Speed Cameras Work and What They're Used For

-

Industry News2025-04-15Thickness and Width Measurement with SinceVision's Advanced Sensor Technology

-

Corporate News2025-04-10SinceVision to Exhibit at the SPS Italia 2025 | Italy

-

Industry News2025-04-10Door Gap Inspection Achieving Flawless Alignment in Vehicle Assembly