Tire manufacturing presents unique challenges that impact vehicle performance and safety. Ensuring optimal quality is critical for safe driving. The advent of advanced 3D laser profiler has transformed the tire inspection process by providing precise, comprehensive scans of tire surfaces. This innovative technology offers deeper insights, enhancing quality control and promoting safer, more efficient manufacturing practices.

What Are the Challenges of Tires?

Producing tires that meet stringent safety standards involves overcoming several challenges:

Tires can develop defects like bulges and dents that may appear minor but can significantly compromise performance and safety. Identifying these subtle irregularities on the sidewall or tread requires ultra-precise inspection tools. Tire imperfections such as radial runout (variations in tire radius during rotation) and lateral runout (sideways deviations) lead to vibrations, reducing ride stability. Accurate detection of these issues is essential to ensure smooth operation and optimal vehicle handling.

Tires are often made from low-contrast, dark materials with complex geometry, making traditional 2D imaging ineffective for defect detection. To overcome this, more sophisticated scanning approaches are required for comprehensive surface analysis.

What Are the Benefits of SinceVision’s 3D Laser Profilers for Tire Manufacturing?

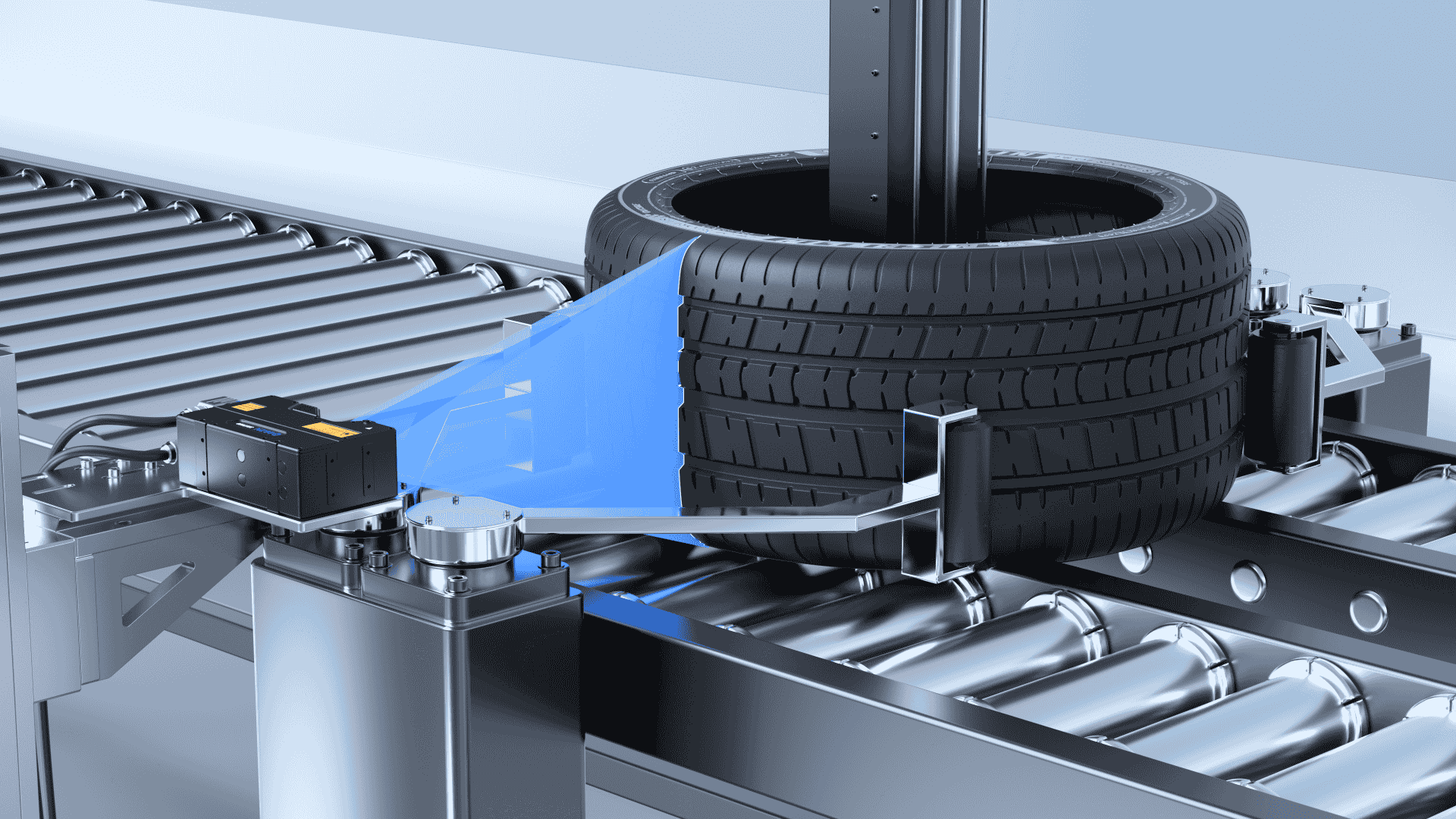

The application of 3D laser profiler, such as through SinceVision’s SR5280 technology, offers numerous advantages:

Fig: SinceVision’s SR5280 3D Laser Profiler

Using a 3D laser profilometer provides unmatched accuracy in surface profiling. Even minute variations and internal defects in tire geometry can be detected, enhancing safety and quality standards. This type of laser profiler collects detailed surface data, helping manufacturers improve consistency and minimize hazardous defects. Unlike traditional methods, 3D laser scanning machines detect both radial and lateral runout accurately by measuring the tire’s entire shape during rotation. This precision reduces vehicle vibrations, improving driving stability and performance.

Industrial 3D laser scanners can perform surface profile measurement quickly and efficiently. This technology reduces the time spent on inspections without sacrificing accuracy, enhancing production line throughput while maintaining high standards. Real-time data acquisition allows manufacturers to make timely decisions to optimize production. Laser surface profilometers provide insights that reduce defects, minimize waste, and enhance production cycles. This enables a proactive approach to quality control, aligning with the principles of modern automation solutions.

3D Laser Profilers for Finished Tire Inspection

The role of 3D laser profiler extends beyond initial tire production, ensuring that finished products meet rigorous safety and performance standards.

Fig: Automatic Studding for Automobile Tires captured by SinceVision’s 3D Laser Profiler

An industrial 3D laser scanner captures a tire's entire surface profile with unparalleled detail. By mapping the full geometry and detecting any undetectable defects with other vision, manufacturers can ensure no defect goes unnoticed. This inspection guarantees that every tire leaving the factory is safe for use on the road. Laser sensors precisely monitor the tire’s radial and lateral runout during final inspections. These accurate measurements minimize rotational inconsistencies, ensuring tires spin smoothly and reducing vibrations that can impact vehicle performance.

Typically, a tire inspection system involves multiple laser profilometers for comprehensive assessment—profiling each sidewall and monitoring tread conditions. This holistic view allows manufacturers to catch defects at every level, safeguarding product integrity before reaching consumers.

By employing advanced laser profiling techniques, manufacturers improve quality control and reduce costs associated with product recalls or defects. This technology reflects the future of manufacturing, merging automation technology and precision to deliver reliable, high-performing products.

Conclusion

The application of 3D laser profiling technology marks a pivotal advancement in tire manufacturing, ensuring defects are identified with unmatched precision. By focusing on comprehensive inspection solutions, manufacturers achieve superior quality control, improve product safety, and enhance overall efficiency. This innovation signifies the critical role of advanced sensors, industrial automation, and smart sensor technologies in shaping the future of manufacturing.

-

Corporate News2025-03-25Safeguarding Food Safety: How SinceVision's 3D Packaging Inspection Transforms the Industry

-

Corporate News2025-03-20VISION 2025 Shanghai Machine Vision Exhibition | Explore SinceVision's Cutting-Edge Machine Vision Solutions

-

Exhibition2025-03-18Smart Manufacturing Innovation: SinceVision's Highlights from Smart Factory + Automation World (AW 2025)

-

Corporate News2025-03-12Unveiling the Secrets of Composite Materials' Strength with High-Speed Cameras and DIC Technology