A 3D laser profiler, also known as a 3D laser profilometer, is an advanced optical device used to measure the surface profile of objects with high precision. By utilizing laser technology, it captures intricate surface details and generates three-dimensional profiles, making it an essential tool for industries requiring accurate measurements. This technology is a cornerstone in applications like quality control, surface inspection, and precision manufacturing. Unlike traditional measuring tools, the 3D laser profiler offers non-contact measurement, ensuring delicate surfaces remain untouched and intact during the inspection process.

How Does a 3D Laser Profiler Work?

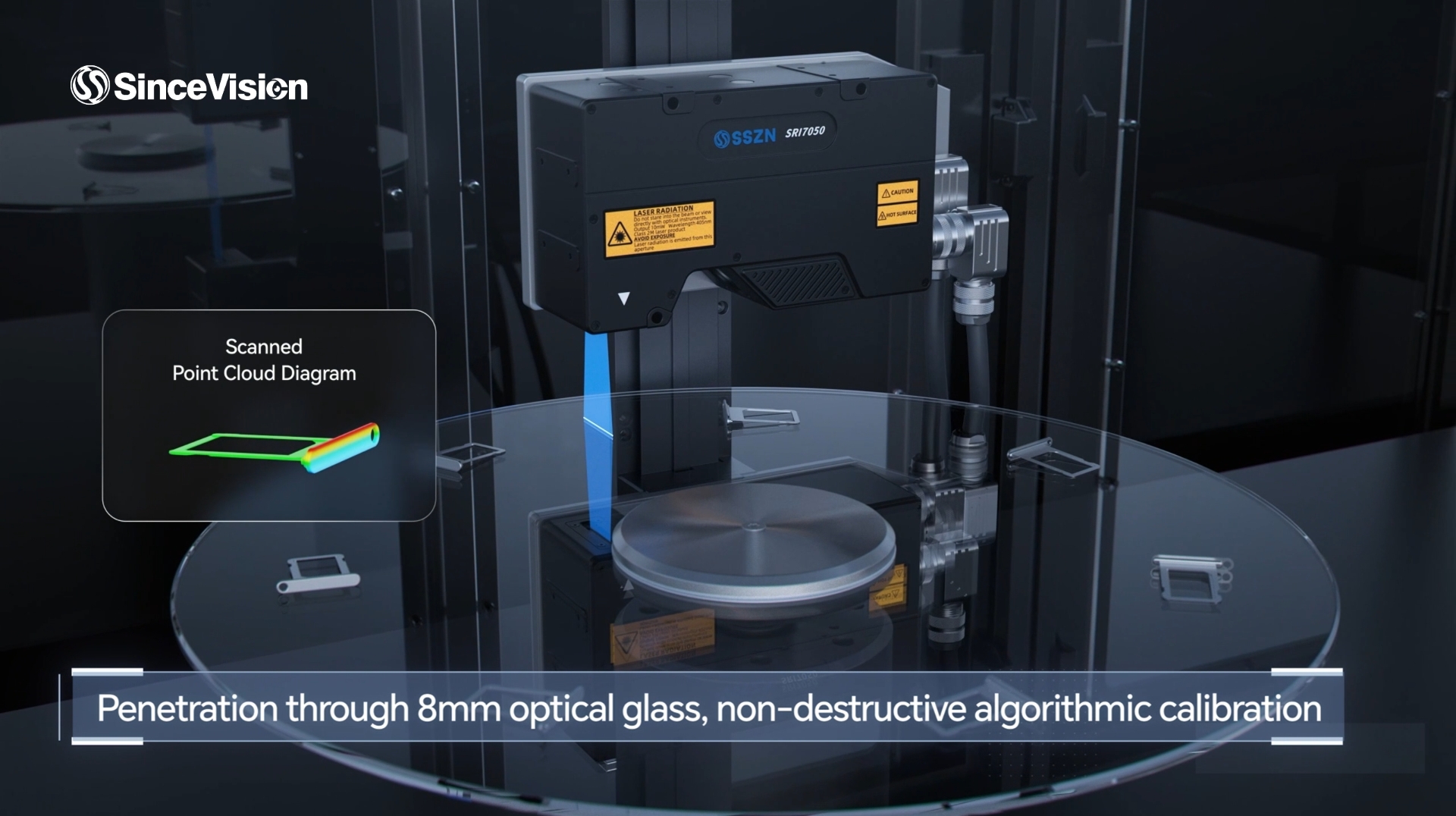

The working principle of a 3D laser profiler relies on laser triangulation. A laser beam is projected onto the surface of the object, and the reflected light is captured by a sensor. The variations in the reflection provide precise information about the object's contours and elevations. This data is then processed to create a detailed 3D model. Advanced devices, such as the industrial 3D laser scanner, can perform measurements at high speeds and resolutions, making them suitable for industries like electronics, automotive, and aerospace. The integration of laser sensors into these devices ensures unmatched accuracy in surface profile measurement.

Image: SRI7080 3D Laser Profiler Inspecting Automotive Tires

Applications of 3D Laser Profilers

The applications of 3D laser profilers and laser profilometers are extensive, ranging from manufacturing to construction. In manufacturing, they play a crucial role in ensuring that components meet strict quality standards by detecting defects, inconsistencies, and deformations. For instance, 3D laser scanning machines are used to inspect PCB boards for flatness and height differences, a vital task in the electronics industry. In construction, the best 3D scanner for construction enables precise measurements of structures and surfaces, ensuring project accuracy and safety. Laser surface profilometers are also utilized in scientific research, where accurate surface data is essential for experiments and analyses.

Benefits of Using a 3D Laser Profiler

The benefits of using a 3D laser profiler are multifaceted, making it an invaluable tool in various industries. Its ability to provide non-contact measurement ensures that even the most delicate surfaces can be inspected without damage. The precision offered by 3D laser scanners, combined with the speed of data acquisition, allows for real-time quality control and streamlined production processes. Additionally, industrial 3D laser scanners and 3D measuring machines can handle complex geometries, ensuring comprehensive surface profile measurements. These devices are versatile, compact, and capable of integrating seamlessly into automated systems, making them a smart choice for modern manufacturing environments.

3D Laser Profilers in Modern Industry

In today's competitive industrial landscape, the adoption of advanced tools like the 3D laser scanner and laser profilometer is no longer optional but necessary. From inspecting micro-components in electronics to analyzing large structures in construction, the versatility of 3D laser scanning machines makes them indispensable. Industrial 3D scanners have revolutionized the way manufacturers and engineers approach quality assurance, delivering precision, efficiency, and reliability. Moreover, the growing demand for laser profilometers in sectors such as healthcare, automotive, and renewable energy highlights their increasing importance in shaping the future of technology and innovation.

Choosing the Right 3D Laser Profiler

Selecting the right 3D laser profiler or laser profilometer depends on specific industry needs and applications. Factors such as resolution, measurement range, speed, and compatibility with existing systems must be considered. For construction applications, choosing the best 3D scanner for construction can significantly enhance project outcomes by delivering accurate and actionable data. Similarly, for precision manufacturing, a laser surface profilometer that offers high-speed measurements and advanced analysis tools can streamline operations. Consulting with industry experts and understanding the capabilities of 3D measuring machines ensures that businesses make the most of this cutting-edge technology.

Conclusion

The 3D laser profiler has emerged as a game-changer in the field of surface profile measurement. Its unparalleled accuracy, speed, and versatility make it a critical tool across industries, from electronics and automotive to construction and research. As the demand for precision and efficiency continues to grow, the role of 3D laser scanning machines, laser sensors, and industrial 3D scanners will only become more prominent. By integrating these advanced tools into their operations, businesses can ensure superior quality, optimized performance, and a competitive edge in the global market.

-

Industry News2024-08-142D and 3D Machine Vision Systems Market to Grow at 12.60% CAGR by 2032

-

Industry News2024-08-07Machine Vision: The Backbone of Semiconductor Manufacturing

-

Exhibition2024-07-10Revolutionizing Manufacturing: AI & 3D Machine Vision Take Center Stage at SinceVision & ZEBRA Seminar

-

Industry News2024-07-22Powering the Future of Lithium Batteries with 3D Laser Inspection

-

Industry News2024-08-29Automated Sorting Systems Market to Reach $13.9 Billion by 2032

-

Corporate News2025-01-09The All-New SinceVision Smart Series High-Speed Camera: Precision, Innovation, and Ultra Performance